Roller Chain Wear and Maintenance

We replace roller chains regularly for a good reason. As the roller chain moves around the sprocket, it naturally wears out. Excessive wear and fatigue can lead to problems. Keeping the chain drive well-maintained ensures your machine stays in good shape over time, so it’s important to reduce wear as much as possible.

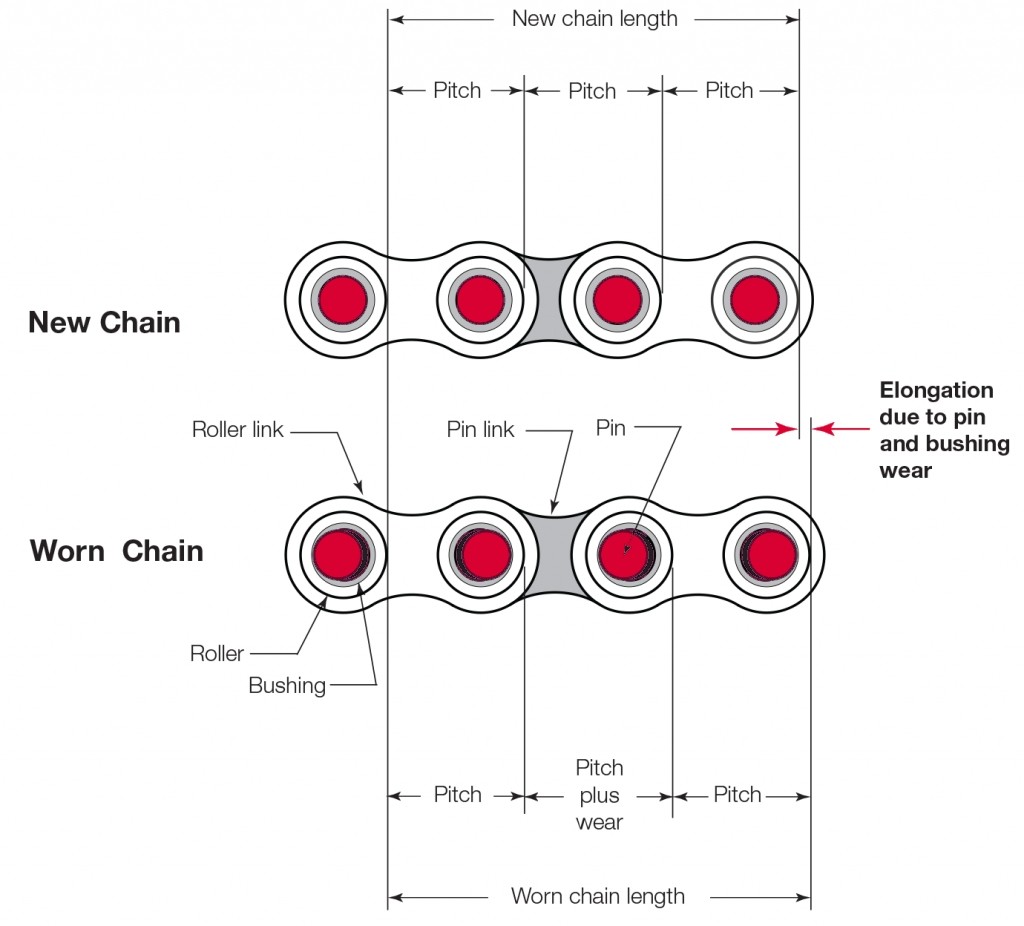

When the roller chain wraps around the sprocket, the pins and bushings experience friction and gradually wear out. This causes the chain to elongate.

Roller Chain Wear

Roller chain wear happens naturally when two metal parts rub against each other during use, causing the material to wear away. Factors like load, speed, lubrication, alignment, and the environment affect how quickly this wear happens. The most common areas for wear are the bushings and pins, which are the main points where the chain moves and bends.

Roller Chain Elongation

As shown above, roller chain elongation happens when the chain gradually gets longer because the pins and bushings wear out. This wear creates extra space between the parts, making the chain longer. As a result, the chain sits higher on the sprocket teeth, which reduces its effectiveness and increases the chance of the chain slipping or coming off. This is often called "chain stretch," even though the chain doesn’t actually stretch. Chains should be replaced when elongated by 3% from their original length.

Common Causes of Roller Chain Wear and Elongation

Several factors can cause roller chains to wear out and elongate. Here are some of the most common ones:

Inadequate Lubrication

Roller chains need proper lubrication to reduce friction and wear between the parts. Without enough or the right kind of lubrication, the chain can wear out quickly and elongate prematurely.

Chain Construction Quality

The quality of the chain's components is crucial. Bushings, an important part of the chain, come in solid and split types. Solid bushings are better at resisting wear than split ones. All Nitro Chains use solid bushings for better durability.

Pre-Loading

Also known as pre-stretching, this process applies a load to a new chain to settle its components and reduce initial elongation. Nitro chains are pre-stretched to meet ANSI and British Standards.

Overloading

Using the chain beyond its design capacity can cause it to stretch and elongate over time due to excessive stress. This is common in heavy-duty industrial applications. Always keep loads within the chain’s maximum working limits.

Contamination

Dirt, dust, and other debris can build up in the chain, increasing friction and wear. Contaminants can also cause corrosion, which speeds up wear and elongation.

Corrosion

Chains in corrosive environments can wear out faster due to chemical reactions or moisture affecting the metal.

Misalignment

If the sprockets are not aligned correctly, the chain will experience extra stress, leading to faster wear and elongation. Misalignment can result from improper installation, worn sprockets, or excessive loading.

High Operating Temperatures

If the chain operates at temperatures above the recommended range, the metal parts can expand and contract, leading to faster wear and elongation.

Solutions of Roller Chain Wear and Elongation

Fortunately, there are several ways to tackle roller chain wear and elongation. Here are some effective solutions:

Proper Lubrication

Use a high-quality lubricant and apply it regularly to reduce friction and extend the chain's lifespan.

High-Quality Chains

Upgrade to better chains like Nitro Chains' new N2 Series, which offer superior wear resistance. These chains come with solid bushings for better durability.

Cleaning

Regularly clean the chain to remove dirt and debris that can cause wear and elongation.

Proper Alignment

Make sure sprockets are properly aligned to reduce stress on the chain and help it last longer.

Load Management

Avoid overloading the chain and keep it within the recommended load limits to prevent excessive wear and elongation.

Temperature Management

Keep an eye on the chain's operating temperature and ensure it stays within the recommended range. Use special high-temperature lubricants if needed to help with wear.

Regular Inspection

Regularly check the chain for signs of wear and elongation to catch problems early and avoid more serious issues.

How often should I lubricate my roller chain?

The frequency of lubrication depends on factors like how the chain is used, the load, and the environment. It's usually recommended to lubricate roller chains every 100 to 200 hours of use. However, it's important to check the manufacturer's guidelines for specific advice on how often to lubricate.

Can I reuse a roller chain after it has elongated?

It is not recommended to reuse a roller chain if it has stretched beyond the manufacturer's limit. Stretching shows that the chain is worn out and won't work well. Using a stretched chain can cause it to fail early, damage the machinery, and create safety risks. It's best to replace the chain with a new one to keep everything running smoothly.

What are the signs of excessive wear in a roller chain?

Excessive wear in a roller chain can show up in different ways. Common signs include noisy operation, uneven or jerky movement, trouble engaging with sprockets, or visible damage to the chain parts. Regularly checking the chain's pitch, roller diameter, and stretch can help spot these issues and decide if the chain needs to be replaced.

Industrial Chain Lubricate

CTS® is a professional roller chain manufacturer, and your partner on the road to success. We have been providing industrial chain solutions for 14 years. We offer various industrial chain options: roller chains, conveyor chains, stainless steel chains, heavy-duty roller chains, double-pitch roller chains, roller chain attachments, roller chain tools, etc. We also support roller chain customization services. We believe that every customer deserves our full attention, and you can depend on our professional technician members to help you find the right product.