Industrial Chain and Sprocket Manufacturer

Assembly Process for Industrial Transmission Products

The precise assembly process is a key step in ensuring the reliability of the sprocket chain

Precision Fitting Assembly Process

Our assembly process is a crucial step in ensuring the precise fit of the final product of the sprocket chain. By strictly controlling each step, we are committed to improving the reliability and performance of our products.

Component Quality Control

Before the assembly process begins, we strictly control the quality of each component. This includes quality inspection of materials, measurement of dimensions, and comparison with design specifications. Only components that have passed strict screening can proceed to the next assembly process.

Process Control and Standardization

We use advanced process control technology to break down the entire assembly process into fine steps. Each step has clear standards and operating procedures to ensure that every worker follows the same standards during the assembly process, reducing the possibility of errors.

Precision Measurement and Adjustment

During critical assembly steps, we use high-precision measurement tools to measure components in real-time. This includes key parameters such as size, clearance and fit. Any slight differences are immediately noticed so adjustments can be made promptly and the product's precise fit can be maintained.

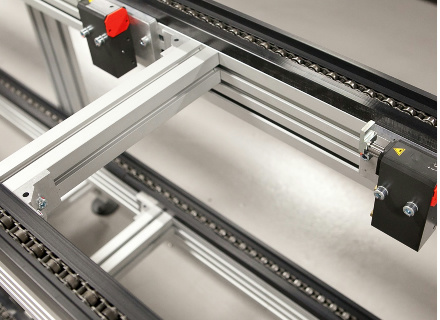

Use Automated Assistance

We introduce automated assisted assembly systems, especially in steps that require high precision and stability. This not only improves efficiency but also reduces the impact of human factors on fit accuracy.

Real-time Feedback and Adjustments

During the assembly process, we established a real-time feedback mechanism. Any deviation from standards is immediately detected and quickly adapted. This timely feedback mechanism ensures real-time control and adjustment of the assembly process, allowing each sprocket chain to achieve a precise fit.

Customer Acceptance Testing

Finally, we conduct customer acceptance testing to ensure that each sprocket chain meets customer needs and expectations. This step is the ultimate verification of the entire assembly process, ensuring that the products received by customers are strictly assembled and can operate reliably.

CTS Case

The sprocket chain customized for us by CTS performs extremely well in harsh agricultural environments. Meticulous control of the assembly process ensures products maintain excellent performance under high loads and corrosive environments. We no longer face frequent damage and repair problems, which greatly improves the reliability and service life of our agricultural machinery.

Thanks to CTS, the sprocket chain maintenance cost of our transportation vehicles has been reduced a lot. Every step is strictly controlled, from the quality of parts to the fit of the final product, which makes us deeply aware of their dedication to quality. We see it The product life is significantly extended, which directly affects our transportation efficiency and economic benefits.

After choosing CTS transmission equipment, the reliability of our equipment has been significantly improved. Zero error ensures the perfect fit of each component, reduces downtime, and truly injects strong power into our production efficiency. Their professional team and advanced technology make us confident in the quality of our products.