V Belt Pulley OR Timing Belt Pulley

Pulleys transmit power in various mechanical systems, from industrial machinery to automotive engines. Two of the most commonly used pulley types are the V-Belt Pulley and the Timing Belt Pulley. Both are designed for specific applications and choosing the right one can significantly impact system performance and longevity. In this post, we’ll dive into the key differences between these pulleys to help you make an informed decision.

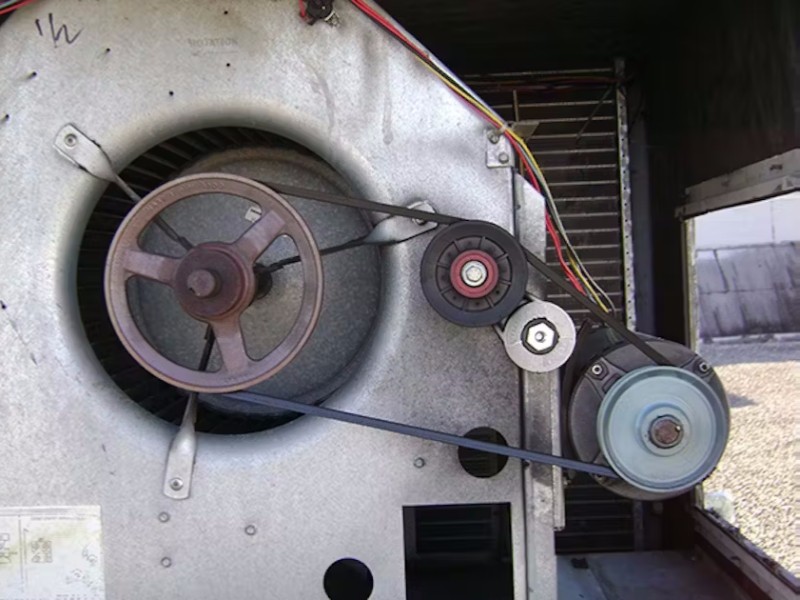

What is V Belt Pulley

A V-belt pulley is designed to work with a V-shaped belt. It is commonly used in power transmission systems where high-speed rotation and flexibility are needed. The V-belt pulley operates by using friction between the sides of the belt and the pulley’s groove. These pulleys are often found in applications such as HVAC systems, conveyor systems, and general industrial machinery. Key benefits of V-belt pulleys include affordability, availability, and ease of maintenance.

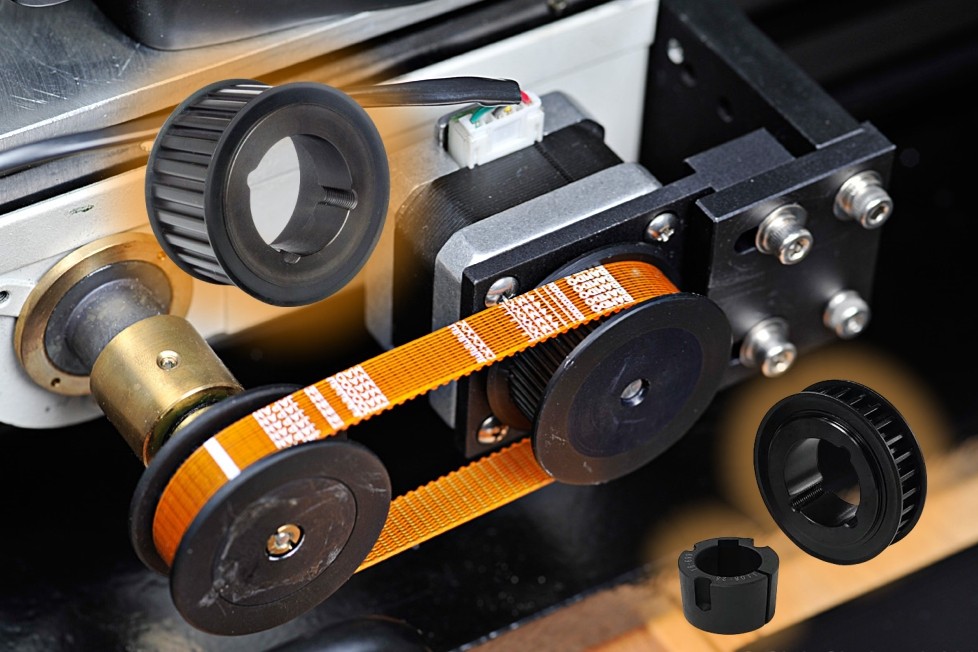

What is Timing Belt Pulley

Timing belt pulleys, unlike V-belt pulleys, are designed for precision. The pulley is grooved to mesh with the teeth of the timing belt, ensuring that the belt and pulley move in sync without any slippage. This makes timing belt pulleys ideal for applications that require exact synchronization, such as internal combustion engines, printers, and CNC machines. The main advantages include high accuracy, reliable power transmission, and durability.

V-Belt Pulley VS. Timing Belt Pulley

Design Differences

V-belt pulleys feature a V-shaped groove while timing belt pulleys have teeth to fit the timing belt. The design of the timing pulley ensures no slippage, while V-belt pulleys allow for some flexibility.

Performance

Timing belt pulleys provide more precise power transmission, making them ideal for high-accuracy applications. On the other hand, V-belt pulleys are better suited for systems where high speeds and loads are common.

Maintenance & Durability

V-belt systems generally require more frequent maintenance due to wear and stretching of the belt, while timing belt systems are known for their longer-lasting performance with less frequent adjustments.

Cost

V-belt pulleys are typically more cost-effective in terms of initial investment. Timing belt pulleys, though more expensive, may offer lower maintenance costs over time due to their durability.

How to choose belt pulley?

When deciding between a V-belt and a timing belt pulley, consider factors such as load capacity, desired precision, speed, and the environment in which the pulley will be used.

For high-speed and high-torque applications, a V-belt pulley may be more appropriate. If your project demands precise synchronization, a timing belt pulley is the better choice.

CTS Belt Pulley Selection

Both V-Belt and Timing Belt pulleys have their advantages, depending on the application. Understanding your specific requirements will help you choose the right pulley for your needs. Whether you prioritize cost-efficiency or precision, selecting the appropriate pulley is key to ensuring optimal system performance. Contact us today for professional guidance in selecting the best pulley for your project!