Metric roller chains are an essential component in various industrial applications, and they are known for their efficiency, durability, and reliability. Unlike ANSI roller chains, which use inch-based measurements, metric roller chains are measured in millimeters, making them ideal for machinery and components manufactured in Europe. Metric roller chains are designed to meet ISO and British Standard specifications, ensuring compatibility with European-manufactured equipment.

We manufacture metric roller chains to meet ISO and British Standards, our standard roller chains be used interchangeably with sprockets from other vendors, simplifying maintenance, and enhancing equipment compatibility.

Metric Roller Chain Pitch Size

Types of Metric Roller Chain

Metric Roller Chain Dimension

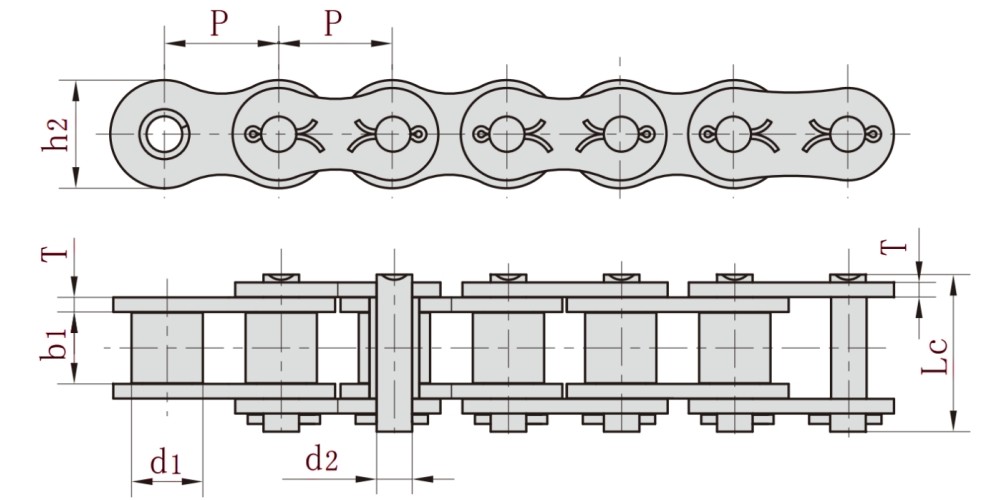

✔ Pitch (P):

Distance between roller centers.

✔ Inner Width (b1):

Distance between inner plates.

✔ Roller Diameter (d1):

Diameter of the rollers.

✔ Plate Height (h2) and Thickness (T):

Dimensions of the chain plates.

✔ Pin Diameter (d2)

The diameter of the connecting pins.

Metric Simplex Roller Chain Dimension

| Chain Size | Pitch |

Roller diameter | Width between

innner plates |

Pin diameter | Pin length |

Inner plate depth | Plate thickness |

Average tensile strength | Weight per meter |

|---|

| P | d1

max |

b1

min | d2

max |

L

max | Lc

max |

h2

max | t/T

max |

Q0 | q |

|---|

| mm | mm |

mm | mm |

mm | mm |

mm | mm |

kN | kg/m |

|---|

| 05B-1 Chain | 8.000 |

5.00 | 3.00 | 2.31 |

8.20 | 8.9 | 7.10 |

0.80 | 5.9 | 0.20 |

| 06B-1 Chain | 9.525 |

6.35 | 5.72 | 3.28 |

13.15 | 14.10 | 8.20 |

1.30 | 10.4 | 0.41 |

| 08B-1 Chain | 12.700 |

8.51 | 7.75 | 4.45 |

16.70 | 18.20 | 11.80 |

1.60 | 19.4 | 0.69 |

| 10B-1 Chain | 15.875 |

10.16 | 9.65 | 5.08 |

19.50 | 20.9 | 14.70 |

1.70 | 27.5 | 0.93 |

| 12B-1 Chain | 19.050 |

12.07 | 11.68 | 5.72 |

22.50 | 24.2 | 16.00 |

1.85 | 32.2 | 1.15 |

| 16B-1 Chain | 25.400 |

15.88 | 17.02 | 8.28 |

36.10 | 37.4 | 21.00 |

4.15/3.1 | 77.1 | 2.71 |

| 20B-1 Chain | 31.750 |

19.05 | 19.56 | 10.19 |

41.30 | 45.0 | 26.40 |

4.50/3.5 | 112.8 | 3.70 |

| 24B-1 Chain | 38.100 |

25.40 | 25.40 | 14.63 |

53.40 | 57.8 | 33.20 |

6.00/4.8 | 178.0 | 7.10 |

| 28B-1 Chain | 44.450 |

27.94 | 30.99 | 15.90 |

65.10 | 69.5 | 36.70 |

7.50/6.0 | 236.4 | 8.50 |

| 32B-1 Chain | 50.800 |

29.21 | 30.99 | 17.81 |

66.00 | 71.0 | 42.00 |

7.00/6.0 | 277.5 | 10.25 |

| 40B-1 Chain | 63.500 |

39.37 | 38.10 | 22.89 |

82.20 | 89.2 | 52.96 |

8.50/8.0 | 394.0 | 16.35 |

| 48B-1 Chain | 76.200 |

48.26 | 45.72 | 29.24 |

99.10 | 107.00 | 63.80 |

12.00/10.0 | 621.6 | 25.00 |

| 56B-1 Chain | 88.900 |

53.98 | 53.34 | 34.32 |

114.60 | 123.00 | 77.80 |

13.50/12.0 | 940.0 | 35.78 |

| 64B-1 Chain | 101.600 |

63.50 | 60.96 | 39.40 |

130.00 | 138.50 | 90.17 |

15.00/13.0 | 1240.0 | 46.00 |

| 72B-1 Chain | 114.300 |

72.39 | 68.58 | 44.48 |

147.40 | 156.40 | 103.60 |

17.00/15.0 | 1550.0 | 60.80 |

Metric Duplex Roller Chain Dimension

| Chain Size | Pitch |

Roller diameter | Width between

innner plates |

Pin diameter | Pin length |

Inner plate depth | Plate thickness |

Transverse | Average

tensile strength |

Weight per meter |

|---|

| P | d1

max |

b1

min | d2

max |

L

max | Lc

max |

h2

max | T

max |

Pt | Q0 |

q |

|---|

| mm | mm |

mm | mm |

mm | mm |

mm | mm |

mm | kN |

kg/m |

|---|

| 05B-2 Chain | 8.000 |

5.00 | 3.00 | 2.31 |

13.9 | 14.5 | 7.10 |

0.80 | 5.64 | 10.2 |

0.33 |

| 06B-2 Chain | 9.525 |

6.35 | 5.72 | 3.28 |

23.4 | 24.4 | 8.20 |

1.30 | 10.24 | 18.7 |

0.77 |

| 08B-2 Chain | 12.700 |

8.51 | 7.75 | 4.45 |

31.0 | 32.2 | 11.80 |

1.60 | 13.92 | 38.7 |

1.34 |

| 10B-2 Chain | 15.875 |

10.16 | 9.65 | 5.08 |

36.1 | 37.5 | 14.70 |

1.70 | 16.59 | 56.2 |

1.84 |

| 12B-2 Chain | 19.050 |

12.07 | 11.68 | 5.72 |

42.0 | 43.6 | 16.00 |

1.85 | 19.46 | 66.1 |

2.31 |

| 16B-2 Chain | 25.400 |

15.88 | 17.02 | 8.28 |

68.0 | 69.3 | 21.00 |

4.15/3.1 | 31.88 | 152.1 |

5.42 |

| 20B-2 Chain | 31.750 |

19.05 | 19.56 | 10.19 |

77.8 | 81.5 | 26.40 |

4.50/3.5 | 36.45 | 229.0 |

7.20 |

| 24B-2 Chain | 38.100 |

25.40 | 25.40 | 14.63 |

101.7 | 106.2 | 33.20 |

6.00/4.8 | 48.36 | 319.2 |

13.40 |

| 28B-2 Chain | 44.450 |

27.94 | 30.99 | 15.90 |

24.6 | 129.1 | 36.70 |

7.50/6.0 | 59.56 | 406.8 |

16.60 |

| 32B-2 Chain | 50.800 |

29.21 | 30.99 | 17.81 |

24.6 | 129.6 | 42.00 |

7.00/6.0 | 58.55 | 508.5 |

21.00 |

| 40B-2 Chain | 63.500 |

39.37 | 38.10 | 22.89 |

154.5 | 161.5 | 52.96 |

8.50/8.0 | 72.29 | 711.9 |

32.00 |

| 48B-2 Chain | 76.200 |

48.26 | 45.72 | 29.24 |

190.4 | 198.2 | 63.80 |

2.00/0.0 | 91.21 | 1130.0 |

50.00 |

| 56B-2 Chain | 88.900 |

53.98 | 53.34 | 34.32 |

221.2 | 229.6 | 77.80 |

3.50/12.0 | 106.60 | 1760.0 |

71.48 |

| 64B-2 Chain | 101.600 |

63.50 | 60.96 | 39.40 |

249.9 | 258.4 | 90.17 |

5.00/13.0 | 119.89 | 2200.0 |

91.00 |

| 72B-2 Chain | 114.300 |

72.39 | 68.58 | 44.48 |

283.7 | 292.7 | 103.60 |

17.00/15.0 | 136.27 | 2750.0 |

120.40 |

Metric Triplex Roller Chain Dimension

| Chain Size | Pitch |

Roller diameter | Width between

innner plates |

Pin diameter | Pin length |

Inner plate depth | Plate thickness |

Transverse | Average

tensile strength |

Weight per meter |

|---|

| P | d1

max |

b1

min | d2

max |

L

max | Lc

max |

h2

max | t/T

max |

Pt | Q0 |

q |

|---|

| mm | mm |

mm | mm |

mm | mm |

mm | mm |

mm | kN |

kg/m |

|---|

| 05B-3 Chain | 8.000 |

5.00 | 3.00 | 2.31 |

19.5 | 20.2 | 7.10 |

0.80 | 5.64 | 13.80 |

0.48 |

| 06B-3 Chain | 9.525 |

6.35 | 5.72 | 3.28 |

33.5 | 34.6 | 8.20 |

1.30 | 10.24 | 30.10 |

1.16 |

| 08B-3 Chain | 12.700 |

8.51 | 7.75 | 4.45 |

45.1 | 46.1 | 11.80 |

1.60 | 13.92 | 57.80 |

2.03 |

| 10B-3 Chain | 15.875 |

10.16 | 9.65 | 5.08 |

52.7 | 54.1 | 14.70 |

1.70 | 16.59 | 84.50 |

2.77 |

| 12B-3 Chain | 19.050 |

12.07 | 11.68 | 5.72 |

61.5 | 63.1 | 16.00 |

1.85 | 19.46 | 101.80 |

3.46 |

| 16B-3 Chain | 25.400 |

15.88 | 17.02 | 8.28 |

99.8 | 101.2 | 21.00 |

4.15/3.1 | 31.88 | 227.10 |

8.13 |

| 20B-3 Chain | 31.750 |

19.05 | 19.56 | 10.19 |

114.2 | 117.9 | 26.40 |

4.50/3.5 | 36.45 | 334.30 |

10.82 |

| 24B-3 Chain | 38.100 |

25.40 | 25.40 | 14.63 |

150.1 | 154.6 | 33.20 |

6.00/4.8 | 48.36 | 493.00 |

20.10 |

| 28B-3 Chain | 44.450 |

27.94 | 30.99 | 15.90 |

84.2 | 188.7 | 36.70 |

7.50/6.0 | 59.56 | 609.50 |

24.92 |

| 32B-3 Chain | 50.800 |

29.21 | 30.99 | 17.81 |

83.2 | 188.2 | 42.00 |

7.00/6.0 | 58.55 | 770.50 |

31.56 |

| 40B-3 Chain | 63.500 |

39.37 | 38.10 | 22.89 |

226.8 | 233.8 | 52.60 |

8.50/8.0 | 72.20 | 1092.50 |

48.10 |

| 48B-3 Chain | 76.200 |

48.26 | 45.72 | 29.24 |

281.6 | 289.4 | 63.80 |

12.00/10.0 | 91.21 | 1710.00 |

75.00 |

| 56B-3 Chain | 88.900 |

53.98 | 53.34 | 34.32 |

327.8 | 336.2 | 77.80 |

13.50/12.0 | 106.60 | 2464.00 |

107.18 |

| 64B-3 Chain | 101.600 |

63.50 | 60.96 | 39.40 |

369.8 | 378.3 | 90.17 |

15.00/13.0 | 119.89 | 3300.00 |

136.00 |

| 72B-3 Chain | 114.300 |

72.39 | 68.00 | 44.48 |

420.0 | 429.0 | 103.60 |

17.00/15.0 | 136.27 | 4125.00 |

180.00 |

Metric Roller Chain Maintenance

✔ Regular Lubrication: This keeps the chain running smoothly and reduces wear.

✔ Proper Tensioning: Ensures optimal performance and prevents premature wear.

✔ Inspection and Cleaning: Regular checks for wear and tear, keeping the chains clean from debris and contaminants.

Proper maintenance is key to extending the life of roller chains. Regular lubrication, tension checks, and timely replacement of worn-out components can prevent common issues like chain elongation and sprocket wear. Understanding and troubleshooting these issues can ensure smooth and reliable operation

Metric Roller Chain Application

Metric roller chains are used across a variety of industries, including:

Manufacturing: For conveyor systems and machinery.

Agriculture: In equipment like harvesters and balers.

Automotive: For engine and transmission systems.

Food Processing: Ensuring hygiene and reliability in operations.

Benefits of CTS® Metric Roller Chain

Durability: Made from high-quality materials to withstand rigorous use.

Efficiency: Designed to provide smooth and efficient power transmission.

Compatibility: Metric roller chains are designed to meet ISO and British Standard specifications, ensuring compatibility with European-manufactured equipment.

CTS® is a professional roller chain manufacturer, and your partner on the road to success. We have been providing industrial chain solutions for 14 years. We offer a wide range of industrial chain options: roller chains, conveyor chains, stainless steel chains, heavy-duty roller chains, double-pitch roller chains, roller chain attachments, etc. We also support roller chain customization services. We believe that every customer deserves our full attention, and you can depend on our professional team members to help you find the right product.