The Difference Between #40 Roller Chain and #41 Roller Chain

When it comes to roller chains, choosing the right one can make or break your machinery's performance. But what's the difference between #40 and #41 roller chains? These two roller chain types might look similar, but subtle differences in size, strength, and application can significantly impact their use. Understanding these differences between the #40 and #41 roller chains will help you make an informed choice.

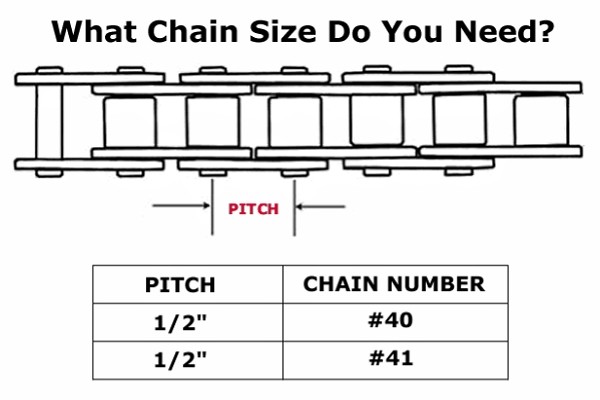

40 Roller Chain VS 41 Roller Chain Dimension

| Chain Pitch | 0.5 inches | 0.5 inches |

| Chain Roller Diameter | 0.312 inches | 0.306 inches |

| Chain Width | 0.312 inches | 0.25 inches |

| Application | For heavy-duty tasks | For lighter-duty applications |

Offer high tensile strength | For lighter and narrower than #40 chains | |

Ideal for long-term, demanding applications | Cost-effective and easier to hand |

Choosing 40 Roller Chain Or 41 Roller Chain

Assessing Between 40 and 41 Roller Chains

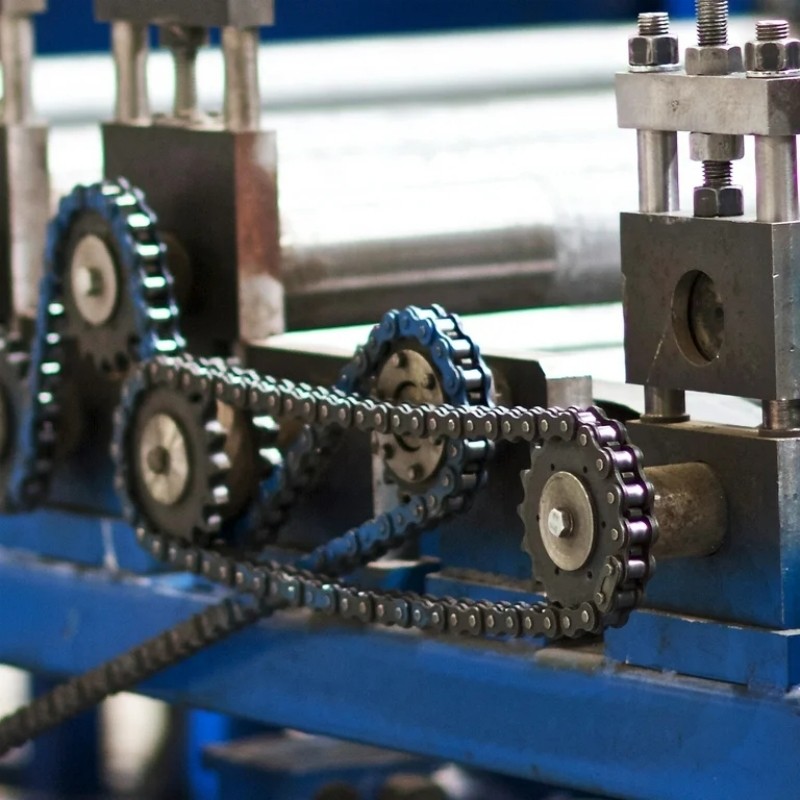

The #40 roller chain has a higher tensile strength, making it suitable for heavy-duty applications like industrial machinery and agricultural equipment. The #41 roller chain, with its lower tensile strength, is better suited for lighter loads.

40 roller chains last longer in harsh environments, but regular maintenance can extend the life of both roller chain types.

Common Issues with Roller Chain

Roller Chain Overloading

Exceeding the load limit of a roller chain, especially the #41 roller chain, can cause elongation and failure.

Roller Chain Misalignment

Improper alignment between sprockets and roller chains leads to uneven wear and reduces efficiency.

Roller Chain Replacement Real-Cases

A manufacturing plant switched from #41 to #40 roller chains for a conveyor system, which improved durability and reduced downtime by 20%. Investing in the right roller chain for the job pays off in performance and longevity.

CTS® | Professional Roller Chain Supplier

CTS®-ChinaTransmissionS is a professional roller chain supplier with over 14 years in the power transmission industry. Our experienced technical team always learns the latest manufacturing technology. We would be a better choice for you to build a long-term and stable cooperation with. We can provide priority service and fast response the first time. In addition, we can also offer high-quality roller chains at a competitive price.

We offer a wide range of industrial chain options: roller chains, conveyor chains, stainless steel chains, heavy-duty roller chains, double-pitch roller chains, roller chain attachments, etc.

If you have any questions about roller chains, please contact us to help you.

CTS® Roller Chains Test and Quality Control Equipment

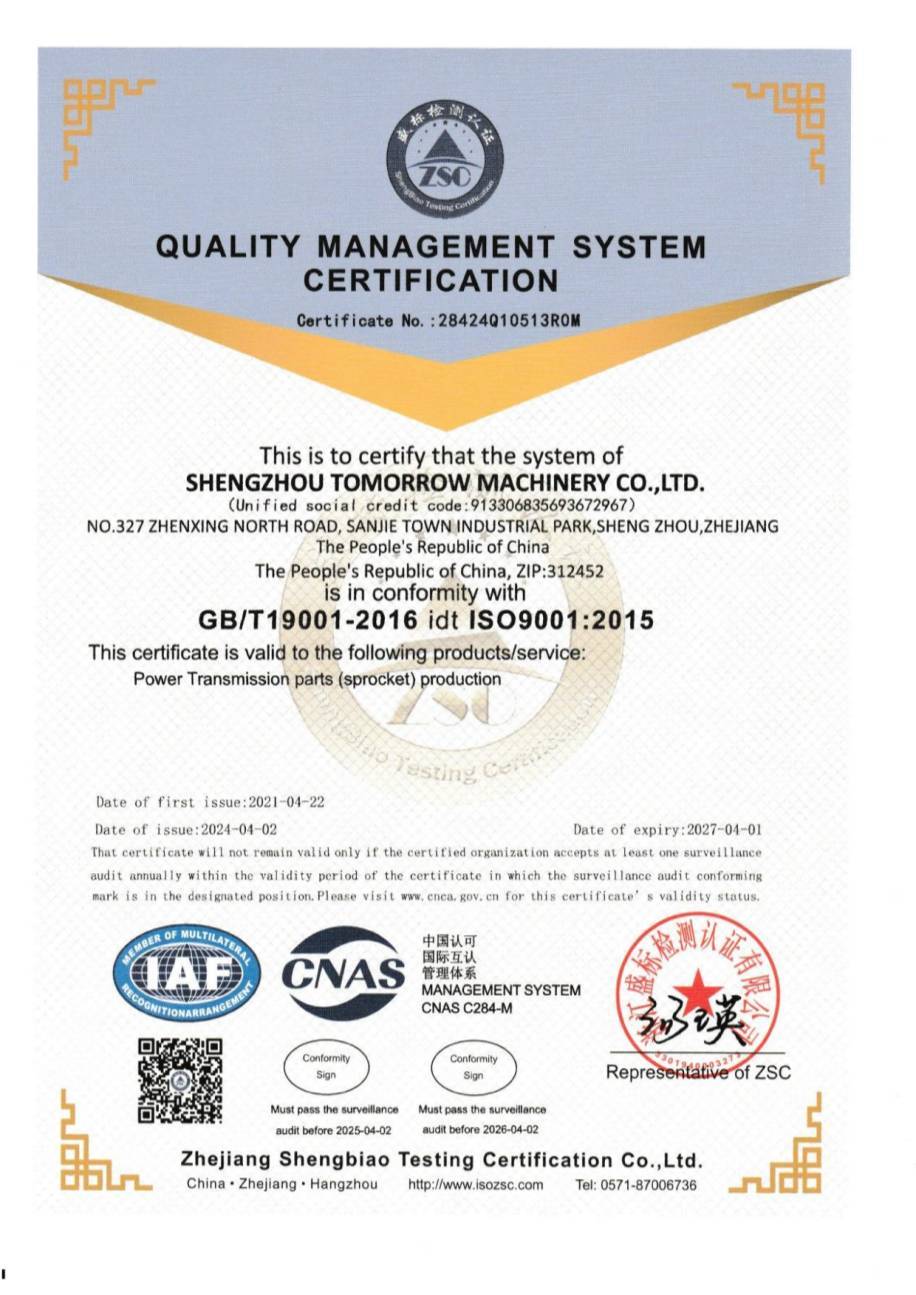

CTS® Quality Certifications

Roller Chain FAQs

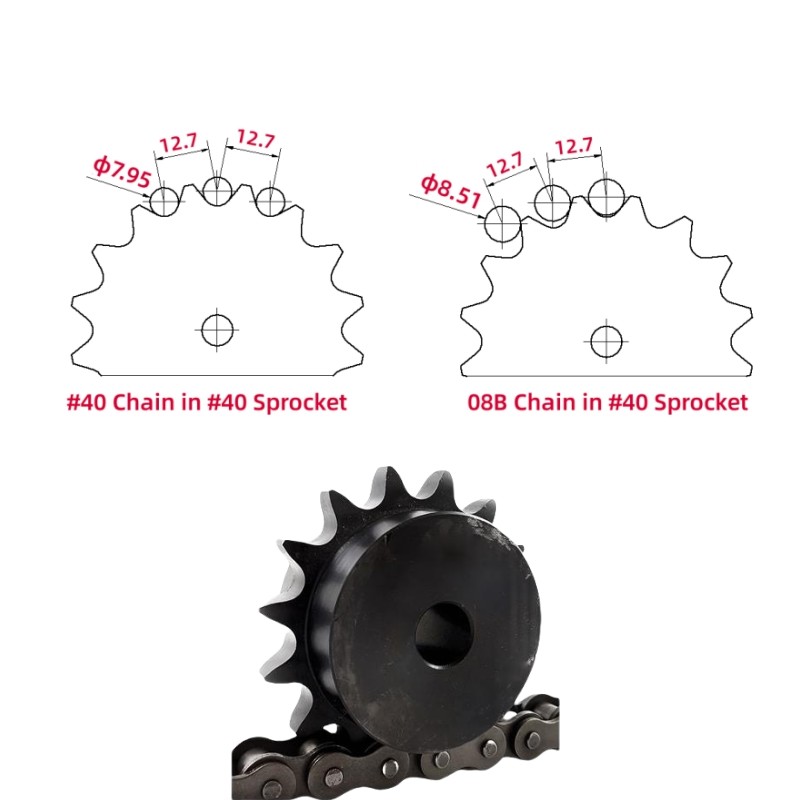

Can I interchange the #40 and #41 roller chains?

No, their slight differences in dimensions may cause compatibility issues with chain sprockets.

Are #40 and #41 chains compatible with the same sprockets?

Not always. Check the sprocket specifications to ensure compatibility.