Guide to ANSI Roller Chain in Industrial Applications

What is ANSI Roller Chain?

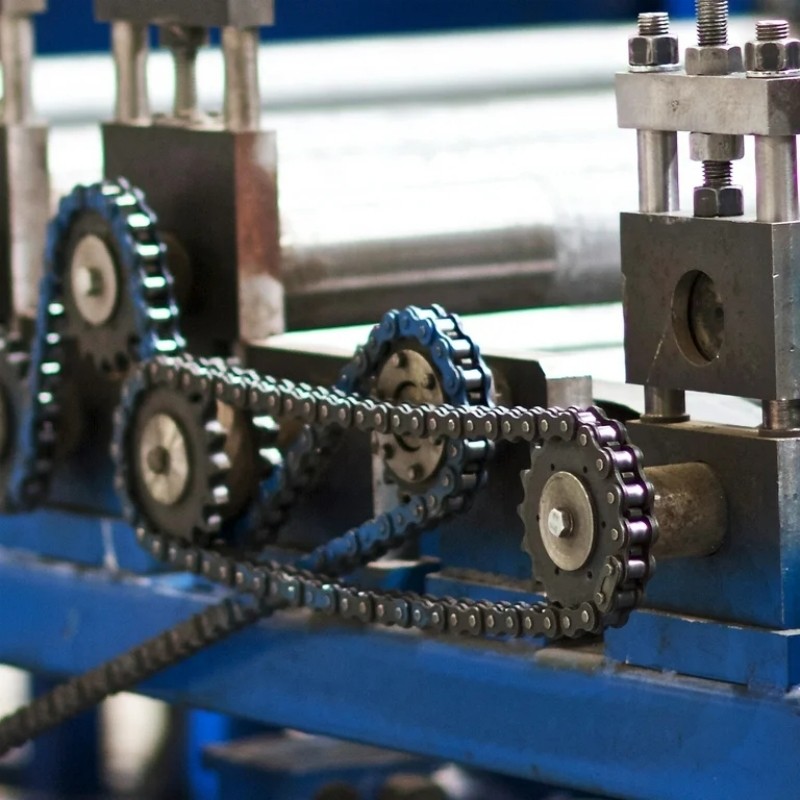

ANSI Roller Chain is a roller chain that complies with the American National Standards Institute (ANSI) specifications and is widely used in the power transmission of industrial equipment. It consists of chain plates, rollers, pins, sleeves, and other components, and transmits power by meshing with the sprocket.

CTS® Roller Chain features:

High-performance Material

Wide-waist Link Plates

Nitro-Carburizing Compound Heat Treating

ANSI Roller Chain Specifications and Size

ANSI standards ensure consistent size, strength, and performance of roller chains, making selection and replacement easy. Here are a few key parameters:

Chain Pitch: The basic size unit of the chain, such as 1/2 inch, or 5/8 inch.

Chain Roller Diameter: affects the meshing effect with the chain sprocket.

Chain Plate Thickness: Determines the load-bearing capacity of the chain.

Common roller chain models

#40 Roller Chain: Suitable for lightly loaded equipment.

#50 Roller Chain: Medium load application.

#80 Roller Chain: Heavy-duty industrial applications.

ANSI Roller Chain Size

ANSI Roller Chain Application

ANSI Roller Chain is widely used in industry, and typically used in conveying systems, lifting equipment, and power transmission applications.

ANSI Roller Chain Advantage

High reliability: solid structure and low failure rate.

Low maintenance costs: long service life and simple maintenance.

Strong adaptability: can be used in high temperature, humid, or corrosive environments (choose appropriate materials).

Manufactured using high-performance material (45Mn) and enhanced through nitrocarburizing compound heat treatment, CTS® roller chains offer extended durability and help minimize machine downtime.

How To Choose Roller Chain?

Selecting the appropriate roller chain requires consideration of the following steps:

1) Determine load and speed: Select a model based on equipment power and speed.

2) Considering environmental factors: such as high temperature or corrosive environments, you can choose stainless steel or nickel-plated roller chains.

3) Matching chain sprockets: Make sure the roller chain and chain sprockets are the same size to avoid meshing problems.

Roller Chain Maintenance

Wear check: measure the chain elongation, if it exceeds 1-3%, it is recommended to replace it.

Tension adjustment: maintain appropriate tension and avoid being too tight (increased wear) or too loose (tooth skipping).

Roller Chain Skipping

Reason: The chain is too loose or the sprocket is worn.

Solution: Adjust the tension or replace the sprocket.

Roller Chain Broken

Reason: overload or insufficient lubrication.

Prevention: Make sure the load is within specifications and lubricate regularly.

CTS | Professional Roller Chain Supplier

CTS®-ChinaTransmissionS is a professional roller chain supplier with over 14 years in the power transmission industry.

As a professional roller chain supplier, our experienced technical team always learns the latest manufacturing technology.

We offer various industrial chain options: roller chains, conveyor chains, stainless steel chains, heavy-duty roller chains, double-pitch roller chains, roller chain attachments, etc.

If you want to replace your roller chains or have any questions about roller chains, please contact us.