Comprehensive Guide to Roller Chain Maintenance

Proper Roller Chain Lubrication

Lubrication reduces friction between the pin and bushing, and the bushing and roller, preventing metal-to-metal wear and corrosion, which is the most common cause of roller chain failure according to experts.

Types of chain Lubricant:

The best option is a high-quality SAE non-detergent petroleum-based oil. The viscosity should be selected based on chain size and ambient temperature.

| Roller Chain Size (ANSI/Metric) | 14℉ -- 32℉ | 32℉ -- 104℉ | 104℉ -- 122℉ | 122℉ -- 140℉ |

| #25-#50 (06B-10B) | SAE10 | SAE20 | SAE30 | SAE40 |

| #60-#80 (12B-16B) | SAE20 | SAE30 | SAE40 | SAE50 |

| #100 (20B) | SAE20 | SAE30 | SAE40 | SAE50 |

#120-#240 (24B-48B) | SAE30 | SAE40 | SAE50 | SAE50 |

Frequency and Methods:

Frequency depends on operating conditions, load, and environment.

For manual roller chain lubrication, apply oil every 8 hours or sooner if joints are dry. Drip lubrication should be at 15-30 drops per minute, while other methods like oil bath or disc slinger require monitoring, ensuring oil reaches the pitch line.

Correct Roller Chain Tensioning

Proper tension ensures optimal power transmission, prevents slippage, and extends chain life by reducing stress and wear.

Excessive roller chain tightness can cause rapid wear and lubricant loss, while too loose a chain can lead to vibration and damage.

Checking Chain Tension:

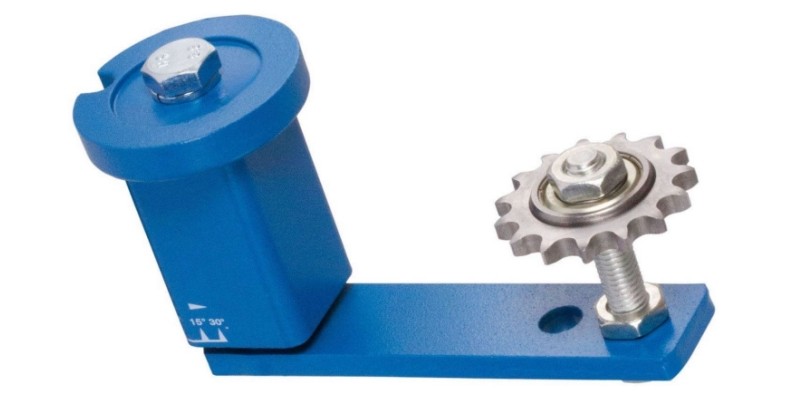

Use a tensiometer, holding it at the midpoint between two teeth on the lower chain, applying load to make it taut but not too tight. Alternatively, check slack; for normal drives, adequate slack should be 4% of the chain span (e.g., 1.86" for a 46.5" span).

Adjusting Chain Tension:

Loosen or tighten the roller chain tensioner per the manufacturer's instructions, which may involve manually adjusting or adding/removing linkages. Steps include:

Determine the correct tension from the manual.

Ensure the chain is seated properly on sprockets.

Use a tensiometer to measure, then adjust and re-check.

Test flexibility by bending the chain sideways; slight movement is required.

Regular Inspection for Roller Chain Wear

Regular inspection prevents unexpected failures by identifying wear early. Roller chain wear can reduce the work-life significantly.

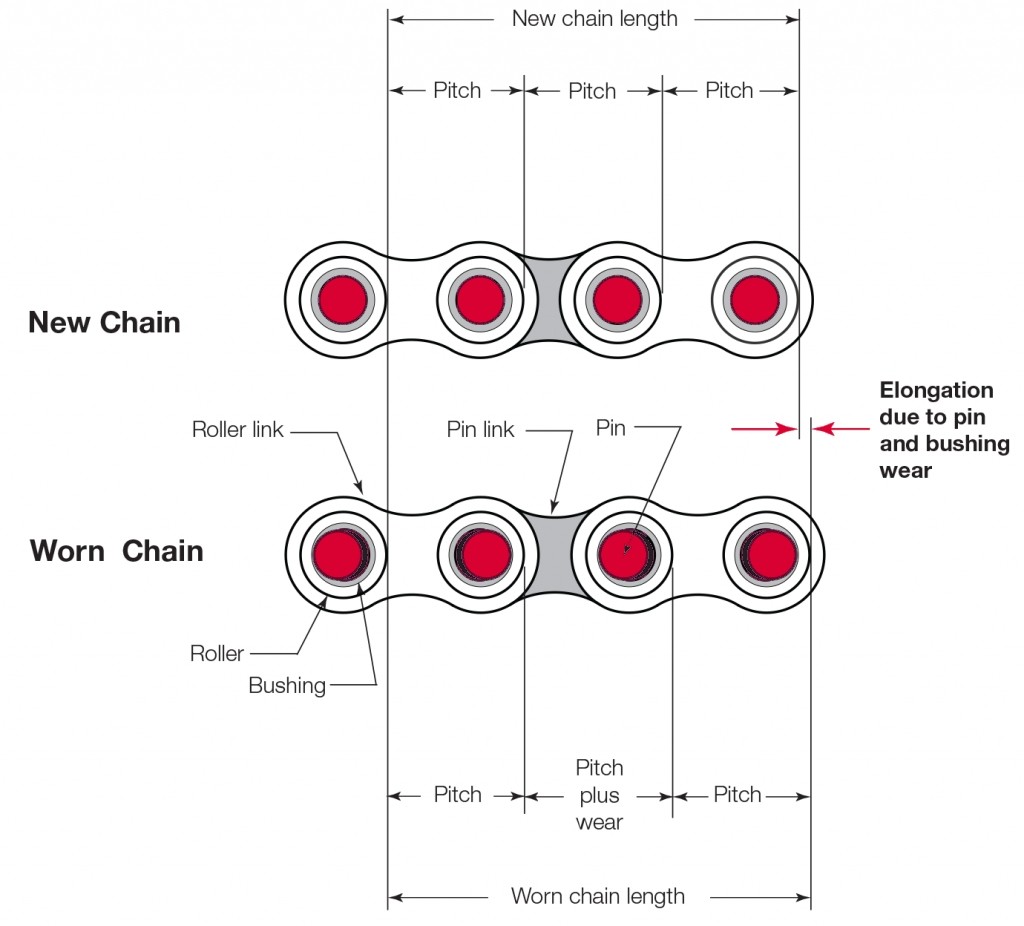

Look for roller chain elongation, damaged links, or worn sprockets.

Measure wear by:

Pitch Measurement: Measure the distance between two adjacent roller pins using a caliper or pitch gauge. If it exceeds the manufacturer's recommended tolerance, replace the chain.

Roller Diameter: Use a micrometer to measure at various points; replace if below the specified minimum.

Replace if wear indicators are met. Also, consider the roller chain's elongation; if the distance between ten links exceeds the limit, it's time for a replacement.

Proper Alignment

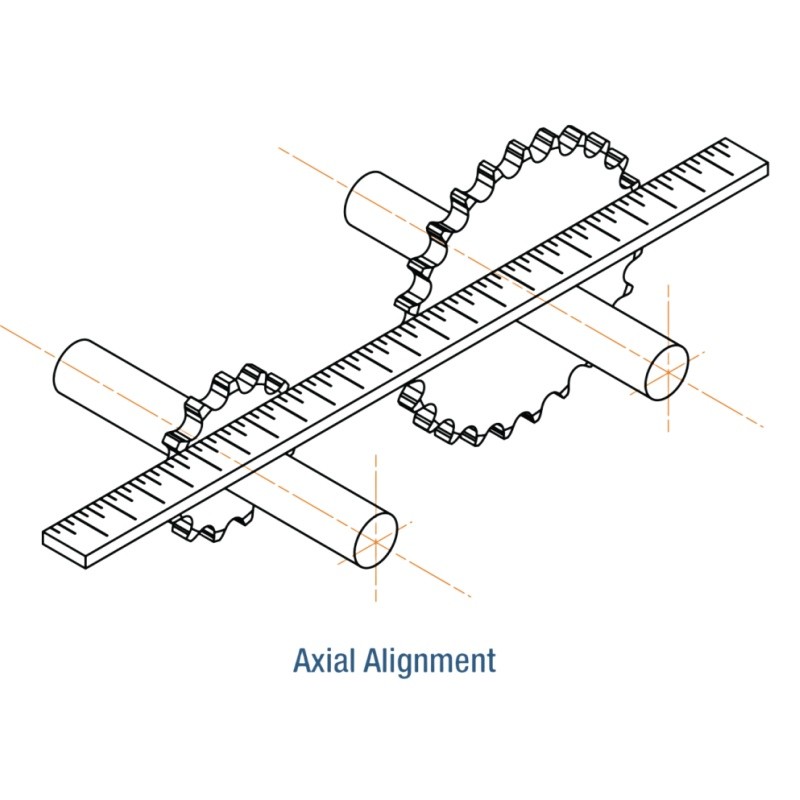

Misaligned sprockets cause the chain to move off-center, leading to uneven wear, noise, and potential failures. Proper alignment distributes load evenly, enhancing service life.

Checking Alignment: Use a straightedge across the face of both sprockets to ensure they are square, or use a laser level for accuracy.

Correcting Misalignment: If misaligned, loosen set screws in one or both sprockets and adjust as necessary. Re-tighten set screws and re-check to ensure alignment, disconnecting power, and removing chain guards for safety.

Follow a Maintenance Schedule

Schedule Details: Divide tasks into:

Smaller Tasks (every 3 months): Chain adjustments, oil and filter changes, and minor inspections for tension and alignment.

Larger Tasks (annually): Cleaning components, aligning shafts, relubricating the whole machine, replacing or servicing worn side plates and sprockets, and unclogging feed pipes, as per Machine Design.

By implementing these top 5 maintenance tips, you can significantly extend the life of your roller chain, reduce downtime, and maintain optimal performance. Regular lubrication, correct tensioning, wear inspections, proper alignment, and a maintenance schedule are key to achieving these benefits.

If you want to reduce machine downtime and improve work efficiency, consider using our high-quality roller chains.

CTS®-ChinaTransmissionS is a professional power transmission products supplier with over 14 years in the power transmission industry. Visit our website for more information or to explore our product range.