Industrial Chain and Sprocket Manufacturer

Wholesale Supply

For You

150,000 Products

Complete variety

More than 14 Years

Trust and experience

ANSI, ISO

Satisfaction guaranteed

PRODUCT FINDER

Roller Chain Size Chart | Roller Chain Dimension Chart

Roller Chain Size Chart

Our Roller Chain Size Chart comprehensively lists frequently requested roller chain configurations and sizes. Roller chain sizes and standards can vary significantly across industries and equipment categories. To aid in your search, we have created the most extensive roller chain size chart available, covering single to multiple-strand designs, as well as duplex and specialty types of chains.

Our roller chain size chart simplifies the process. It provides essential information to ensure an informed purchase, perfectly meeting your machinery's strength and load-carrying capacity requirements.

Roller Chain Size Chart By Chain Type

- ANSI | Single Strand

- ANSI | Double Strand

- ANSI | Triple Strand

- ANSI | Multiple Strand

- ANSI | Hollow Pin

- ANSI | Heavy Duty Series

- ANSI | Cottered Type

- Metric | Single Strand

- Metric | Double Strand

- Metric | Triple Strand

- Metric | Hollow Pin

- Double Pitch

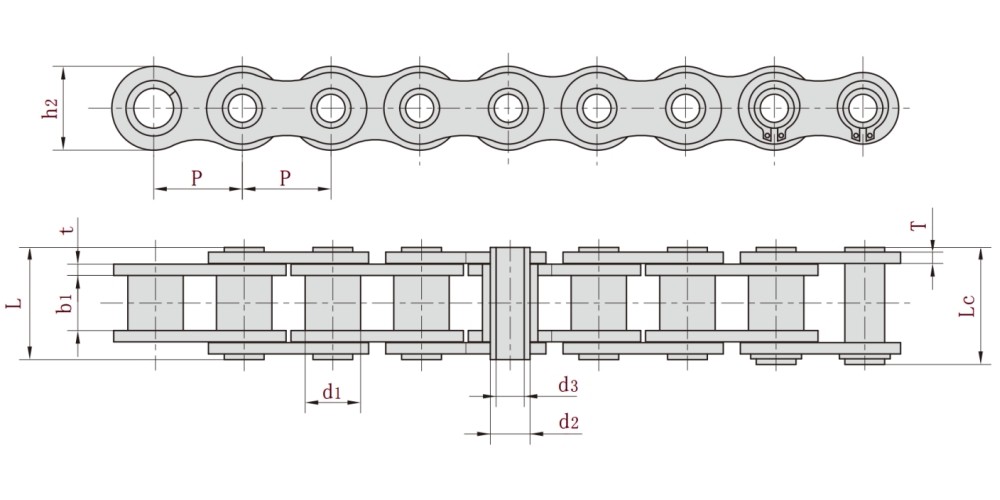

Our roller chain size chart offers comprehensive dimensions and specifications for each single-strand standard ANSI chain size. Whether you're seeking a replacement or determining the appropriate size for your equipment design, this chart streamlines the process, allowing you to seamlessly match your measurements with the provided dimensions for accurate chain identification.

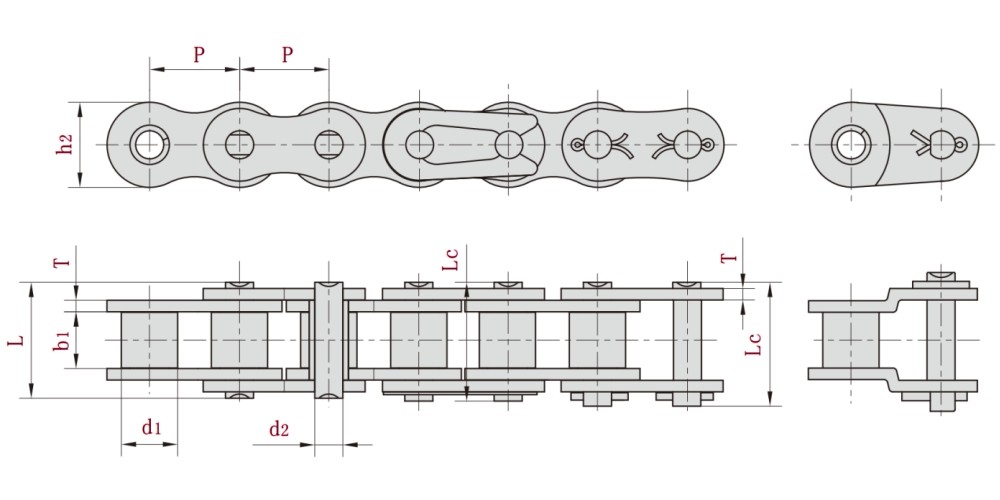

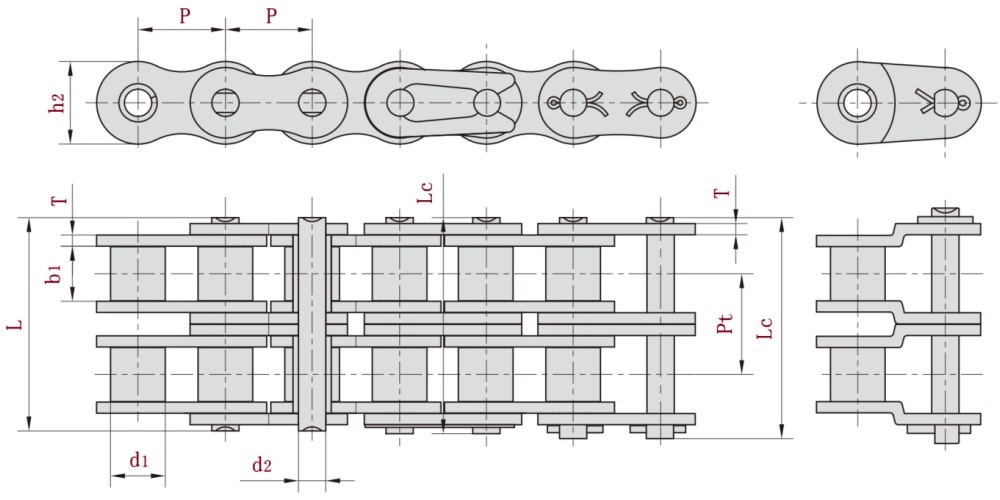

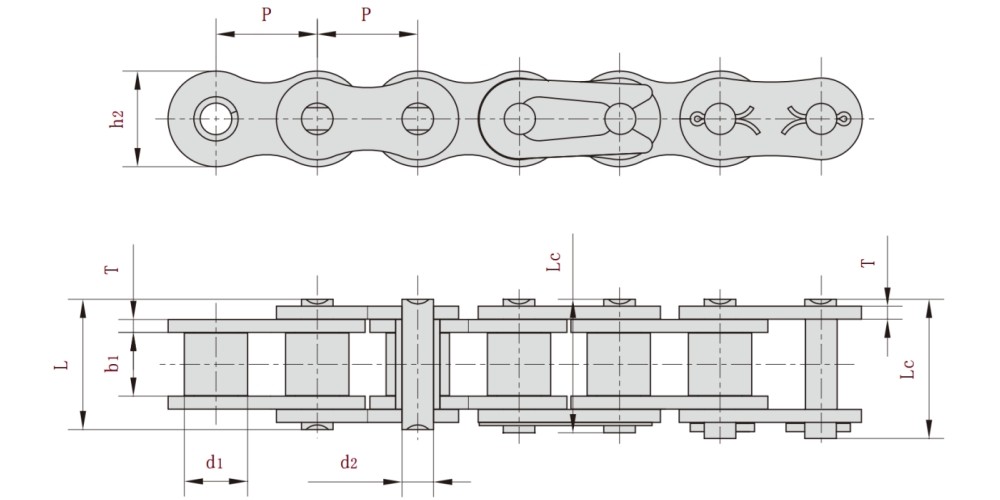

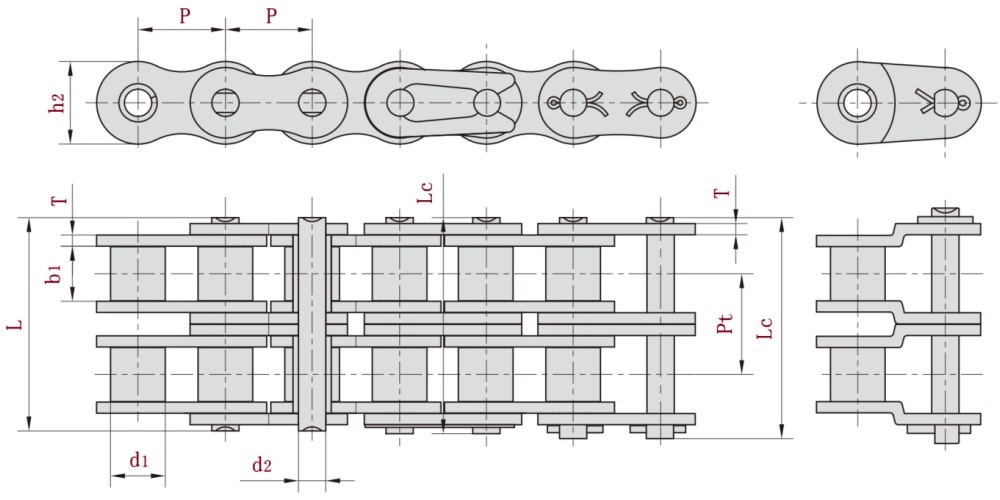

Double-strand roller chains, also known as duplex roller chains, offer significantly higher tensile strengths and working loads compared to single-strand chains. They are commonly used in various drive and conveying applications.

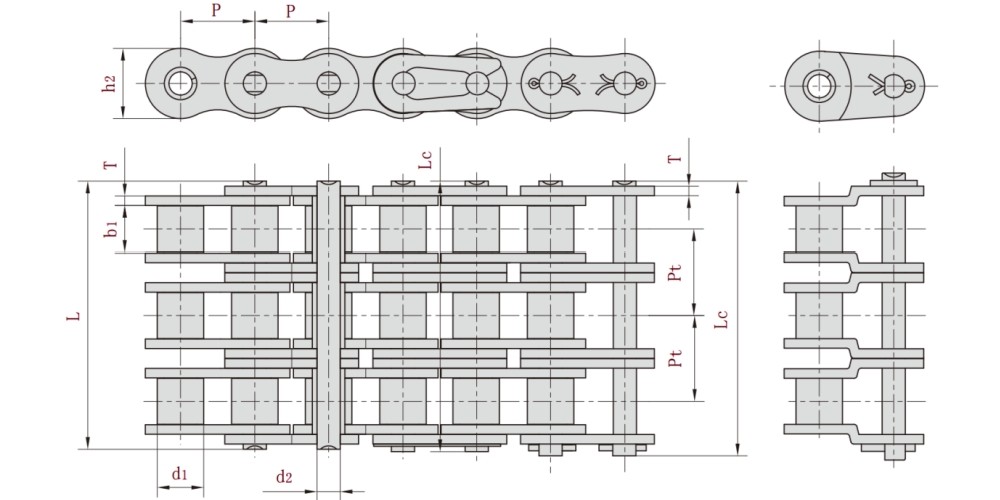

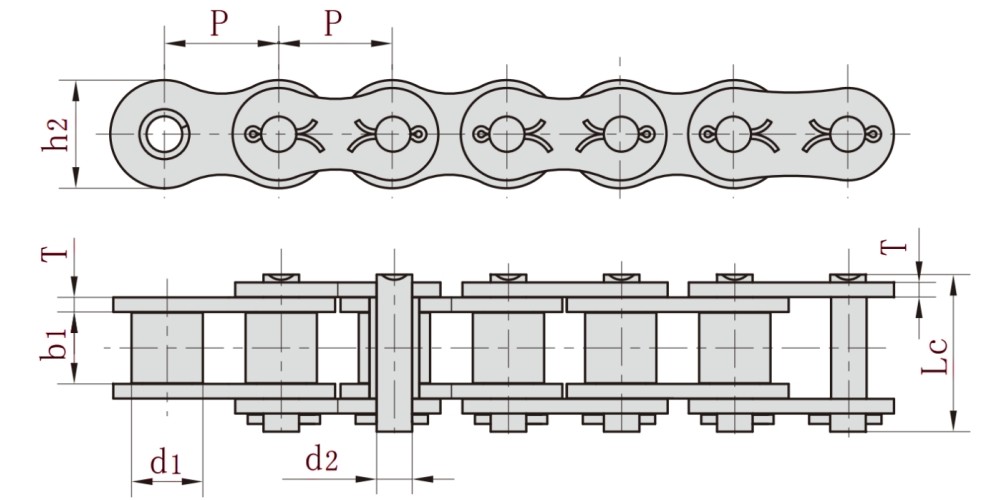

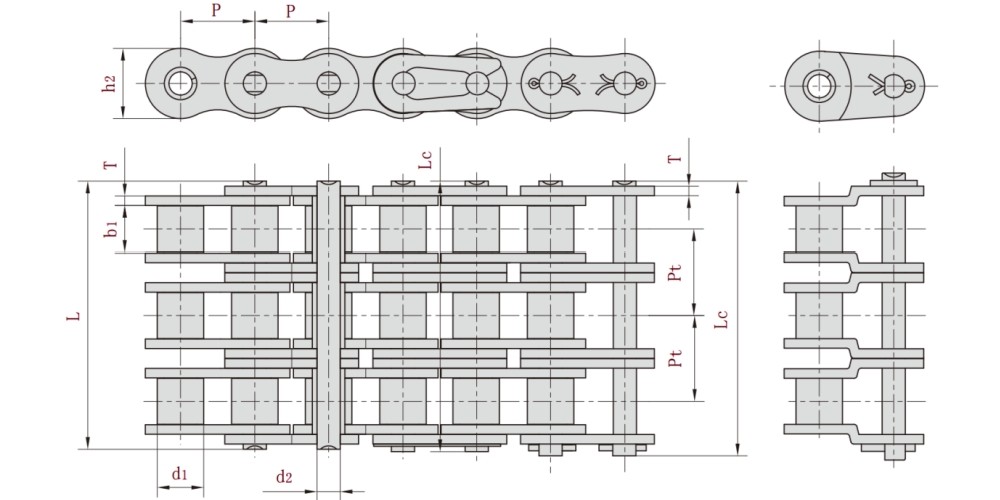

A triple-strand roller chain, also known as a triplex roller chain, features three parallel strands of chain links, offering even higher tensile strength and working load capacities compared to single and double-strand chains. Triplex roller chains are commonly used in industrial machinery, conveyors, and other high-stress environments.

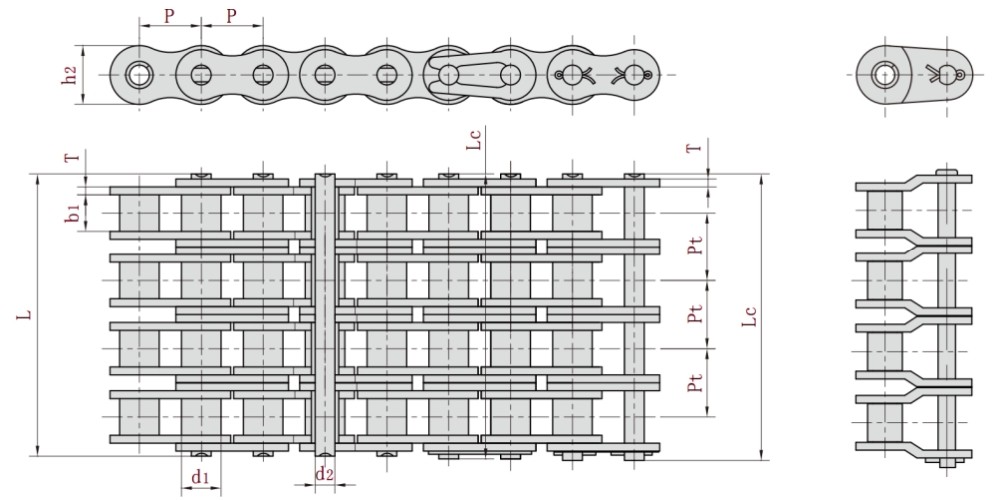

Multiple-strand roller chains consist of two or more rows of single roller chains linked together. These chains provide increased strength, durability, and load-bearing capacity, making them suitable for heavy-duty applications in various industries such as manufacturing, mining, and construction.

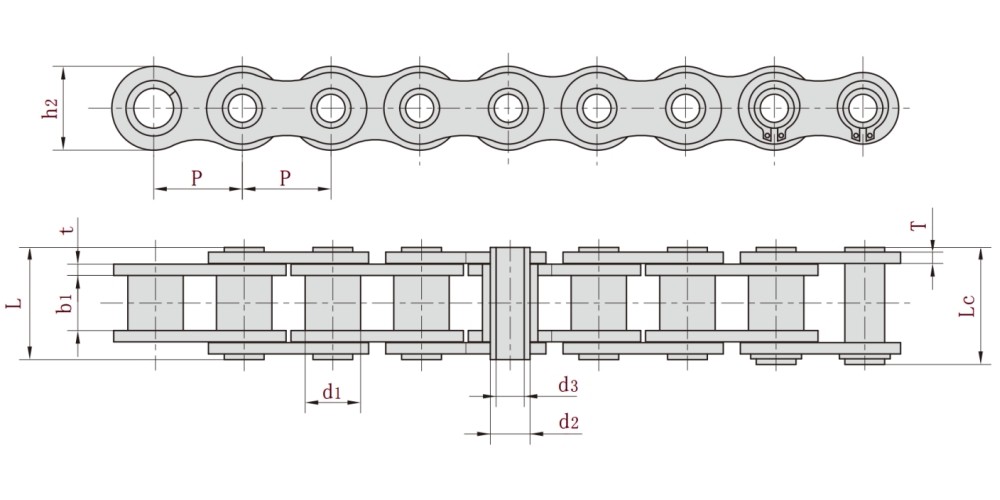

Hollow pin roller chains have a unique link pin design that sets them apart from standard roller chains. Despite this difference, the construction of hollow pin chains is quite similar to that of ANSI standard roller chains. Both types of chains consist of pins, bushings, and small rollers. This similarity in construction allows hollow pin roller chains to be mostly compatible with the sprockets used for the corresponding standard chains.

A heavy-duty roller chain is a type of roller chain designed for high-stress applications where increased strength and durability are crucial. These chains feature thicker side plates compared to standard roller chains, which enhances their strength and fatigue resistance. This construction minimizes stretching and wear over time, making them ideal for demanding applications such as agricultural machinery, construction equipment, and industrial machinery.

Heavy-duty roller chains are available in various configurations, including single-strand (simplex), double-strand (duplex), and triple-strand (triplex) versions, each providing varying levels of strength and capacity. They are manufactured to ANSI standards, ensuring compatibility and reliability across different uses. Additionally, these chains can be produced in riveted or cottered styles, offering flexibility depending on the specific needs of the application.

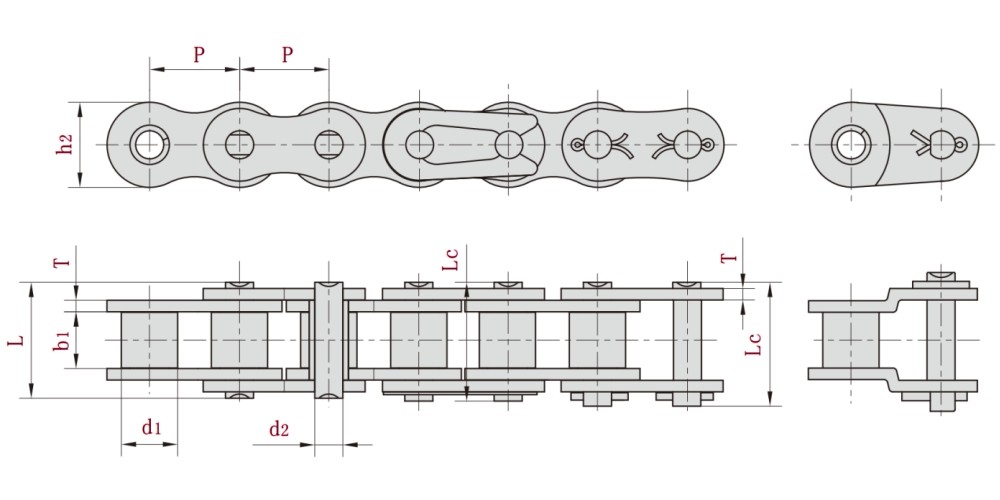

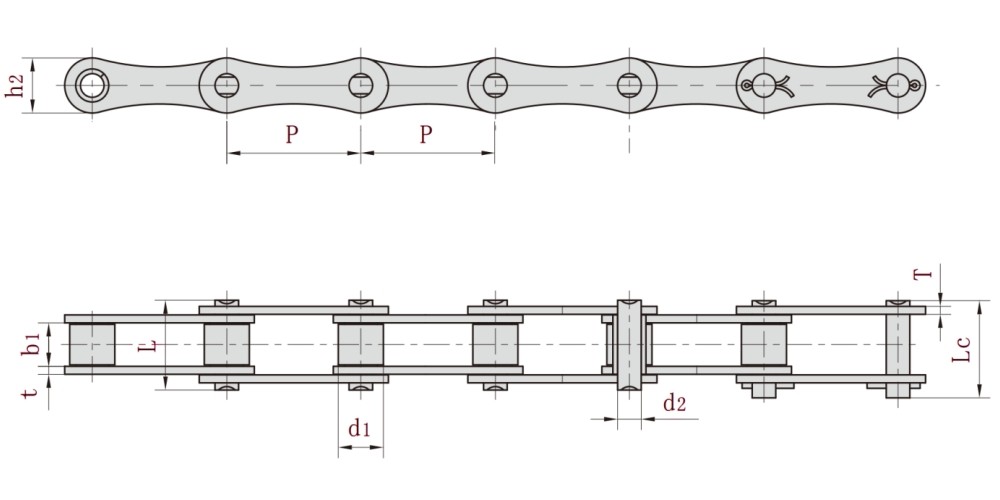

A cottered roller chain is a type of roller chain that uses cotter pins to secure the chain links. Unlike riveted roller chains, cottered chains allow for easier disassembly and maintenance since the cotter pins can be removed without the need for grinding off the pin heads. This design is particularly beneficial in applications where frequent chain adjustments or replacements are necessary. Cottered roller chains are commonly used in heavy-duty industrial applications, including conveyors, agricultural machinery, and mining equipment, due to their durability and ease of maintenance. These chains conform to ANSI standards and are typically made from high-quality carbon steel that is heat-treated for enhanced strength and wear resistance.

A metric single-strand roller chain, also known as a simplex ISO chain, is a roller chain manufactured to ISO British standards. The key dimensions of a metric single-strand roller chain include the pitch (the distance between roller centers), roller diameter, and inner width. These chains are available in various strength grades and materials to suit different load capacities and environmental conditions.

A metric double-strand roller chain, also known as a duplex roller chain, is designed according to British Standards (BS), ISO, and DIN specifications. It features two parallel rows of roller links, enhancing its load-bearing capacity and durability compared to single-strand chains. These chains are commonly used in high-torque and heavy-duty applications, such as industrial machinery and conveyors. Our roller chains are manufactured from high-quality materials, undergo precision heat treatment, and are often shot-peened to improve strength and longevity.

A European standard triple roller chain, commonly known as a triplex chain, is a type of roller chain used extensively in various industrial applications for power transmission. These chains are designed according to the DIN ISO 606 standard, previously known as DIN 8187, and are recognized for their robust construction and durability. The triplex chain consists of three parallel strands of roller chains, offering significantly higher strength and load-bearing capacity compared to single or duplex chains.

European standard hollow pin chains are versatile and widely used in various industrial applications. These chains are designed to allow the insertion of cross rods or attachments directly through the hollow pins, providing great flexibility in the design and application. They come in multiple types, including single and double pitch, with or without rollers, and with or without bushings. The hollow pin feature allows for easy customization and adaptation, making them ideal for use in conveyors and other machinery requiring frequent attachment changes.

A double-pitch roller chain is a specialized type of roller chain designed for applications requiring longer spacing between links compared to standard roller chains. This type of chain features a pitch (the distance between roller centers) that is double that of standard chains, making it suitable for light to moderate load applications, often in conveyor systems.

Double-pitch roller chains are manufactured to ANSI and ISO standards and come in two main types: conveyor series and transmission series. Conveyor series chains typically have straight sidebars and are used in conveying applications, while transmission series chains are used in power transmission with greater durability.

Roller Chain Size

Size of roller Chain

Roller chains are available in a variety of sizes, including single and multiple strands, each with different weight and tensile strength ratings. Smaller pitch chains are used for light to moderate loads, while larger pitch chains handle heavier loads. Our roller chains are standardized according to ANSI or ISO British standards, ensuring design and dimension interchangeability.

Key specification for roller chains:

✔ Size

✔ Pitch

✔ Roller Width and Diameter

✔ Average Ultimate Tensile Strength

Roller Chain Selection

When selecting a roller chain, consider:

Tensile Strength:

Represents the force required to break the chain.

Working Load:

Recommended load for a chain considering various factors.

Application Conditions:

Temperature, corrosion, abrasion, and operational hours.

Speeds/Torque:

Each chain has specific speed and torque limits.

Dimensional Requirements:

Ensure the chain fits within space constraints.

Selecting the right roller chain ensures reliable and efficient performance in your operations.

Roller Chain Size Download

Roller Chain Resource

| Image | Roller Chain Size Chart | Roller Chain Dimension Chart | Description | In stock | More |

|---|

Ask CTS?

Having trouble finding the product you need? Send us an email with your question or message, and we'll quickly respond with tailored solutions. We're eager to hear from you! Expect top-notch precision, reliability, efficiency, and performance. Let's redefine excellence together.

- China's professional power transmission manufacturer

- We offer customized product services and free samples to meet our customers' needs.

- Some of our products are mass-produced and kept in stock, ready for immediate shipment.

- Contact CTS

- Name