Home / All

News

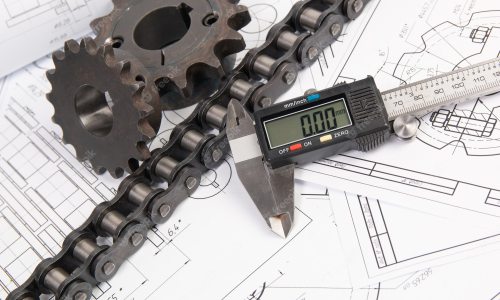

- How to hobbing sprocketHobbing is a common manufacturing process used to produce sprockets with accurate tooth profilesSep 27,2023

- what is the manufacture process of spur racksA spur rack is a type of linear gear with straight teeth that mesh with a pinion gear to convert rotary motion into linear motion.Sep 25,2023

- How to make MN couplingThe MN coupling, also known as the Muffelex Coupling, is a type of flexible coupling used to connect two rotating shafts in machinery. It is designed to accommodate misalignment, reduce vibrations, and transmit torque between the connected shafts. The MN coupling consists of two hubs and an elastomeric element.Sep 25,2023

- How to make MN couplingThe MN coupling, also known as the Muffelex Coupling, is a type of flexible coupling used to connect two rotating shafts in machinery. It is designed to accommodate misalignment, reduce vibrations, and transmit torque between the connected shafts. The MN coupling consists of two hubs and an elastomeric element.Sep 25,2023

- What are the three types of racks?These three types of racks offer different characteristics and application capabilities, allowing them to be applied in various industries and machinery that require linear motion, precision, and power transmissionSep 25,2023

- Timing pulley processThe process of working with timing pulleys typically involves several steps.Sep 22,2023

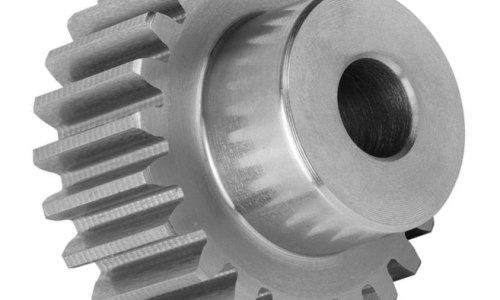

- Design and Production of a GearDesigning and producing a gear involves several steps. Here is a general guide to help you understand the process:Sep 22,2023

- What is the manufacturing process of flexible coupling?The manufacturing process of flexible couplings involves several key steps. The process typically begins with the selection of suitable materials based on the intended application. Different components, such as hubs, flanges, and flexible elements, are then fabricated individually using techniques like casting, machining, forging, or molding. These components are subsequently assembled together, ensuring precise alignment and fit.Sep 18,2023

- What is the difference between Stainless steel sprockets and carbon steel sprockets?Sprocket is a mechanical element used to cooperate with a chain, usually to transmit power and achieve rotational motion. When used in conjunction with a chain, the sprocket transmits the power of the chain to the rotating shaft to realize the movement or rotation of the object.Sep 18,2023

- What are the types of Coupling?Chain Coupling: Interlocking chains transmit torque and provide flexibility for high-torque applications.Sep 18,2023

Jaw Coupling: Two hubs with elastomeric curved jaws provide simplicity, compact design, and vibration damping.

FCL Coupling: Also known as a floating shaft coupling, it uses a membrane design for angular misalignment compensation.

NM Coupling: Lovejoy couplings use elastomeric spider inserts with curved jaws for flexibility and vibration damping. - Internal Gear Shaping 50° helix angleInternal gear shaping with a 50° helix angle refers to the process of manufacturing internal gears with teeth that have a helix angle of 50 degrees.Sep 14,2023

- HOW TO REPLACE THE CHAIN, SPROCKETS AND BUSHESReplacing the chain, sprockets, and bushes typically involves several steps.Sep 14,2023