What is a V Belt Pulley?

V-belt pulleys, also known as V-belt sheaves, are essential in many mechanical and industrial applications. They play a critical role in the power transmission process, ensuring that machinery operates smoothly and efficiently.

A V belt pulley is a device used to transmit power between axles using a V belt. The name comes from the V-shaped groove that runs around the circumference of the pulley, which helps to guide and grip the belt. These pulleys come in various sizes and types, including standard pulleys, variable speed pulleys, and step pulleys, each designed for specific applications and power requirements.

V Belt Pulley Types

European standard pulleys, often referred to as DIN (Deutsches Institut für Normung) pulleys, follow specific European norms such as DIN 2211, ISO 4183, DIN 1651, and UNI 5007. These standards ensure the pulleys meet high manufacturing and performance requirements.

Profile:

Design:

These pulleys use a taper bush system for mounting, ensuring a secure fit on the shaft. The taper bush is characterized by a conical sleeve, which helps in achieving better centering and balance.

American Standard Pulleys

American standard pulleys adhere to ANSI (American National Standards Institute) specifications. These pulleys are common in the North American market and follow standards that cater to different industrial needs.

Profile:

3V, 5V, 8V (for various belt sizes), as well as A/B, C, and D.

Design:

American standard pulleys often use an expansion sleeve system, which is different from the taper bush system. This expansion sleeve allows for easy installation and removal, providing flexibility in maintenance and adjustments.

V Belt Pulley Dimension

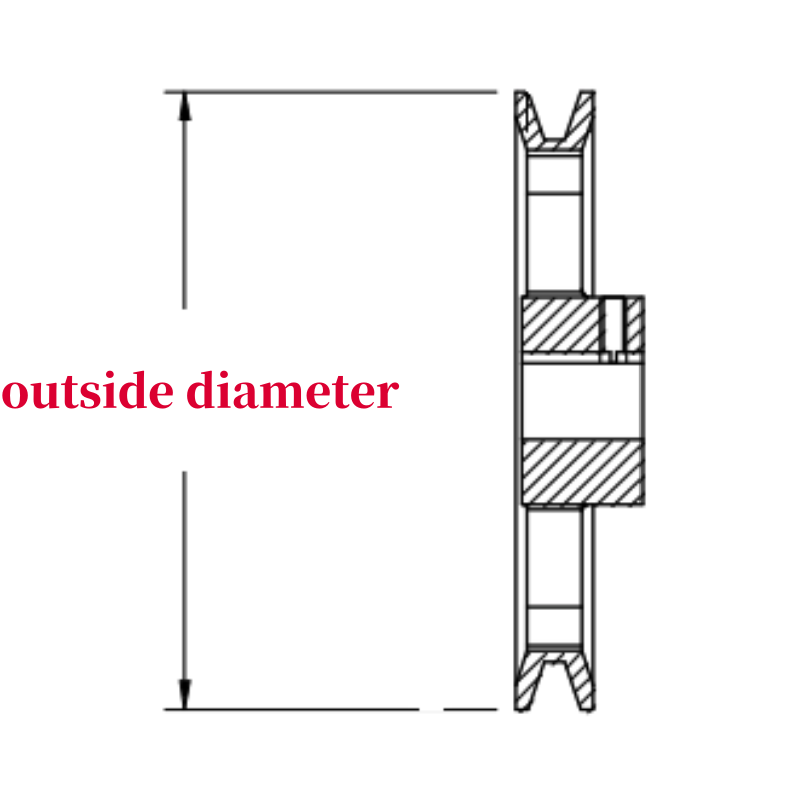

Measure the outside diameter of the pulley.

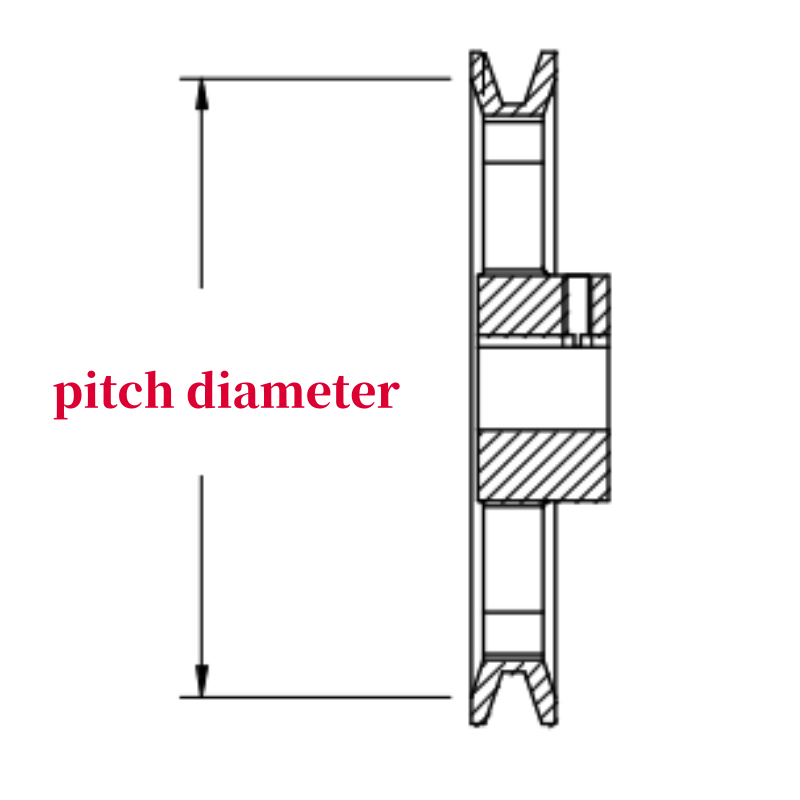

Then measure the pitch diameter. This measurement represents the diameter of the belt itself as it runs in the pulley. If you already know the size of the V-belt, or if the pulley and belt are badly worn, you do not need to perform this step.

Measure the outside diameter of the pulley.

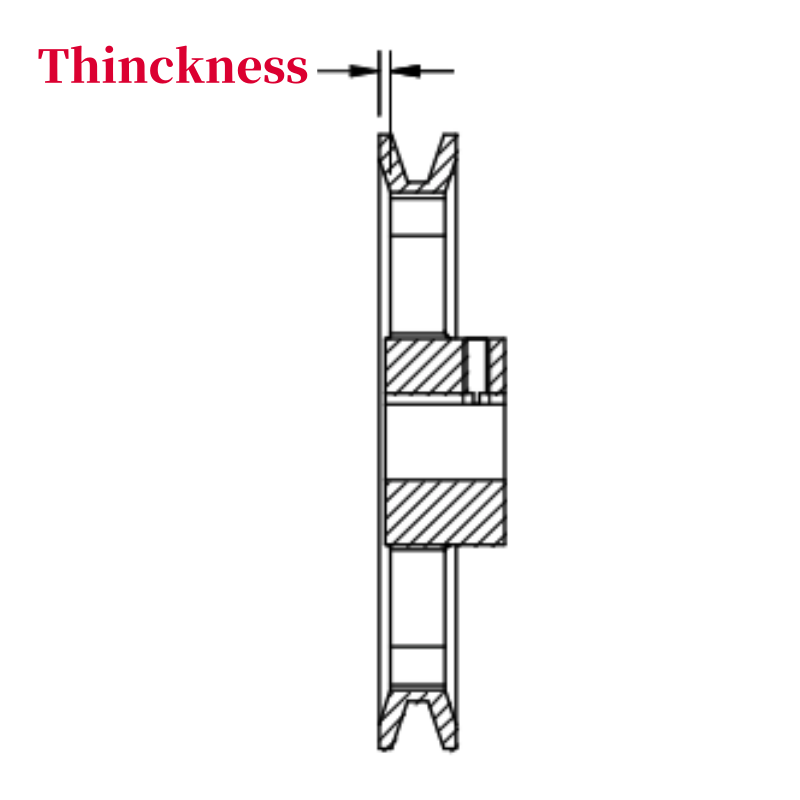

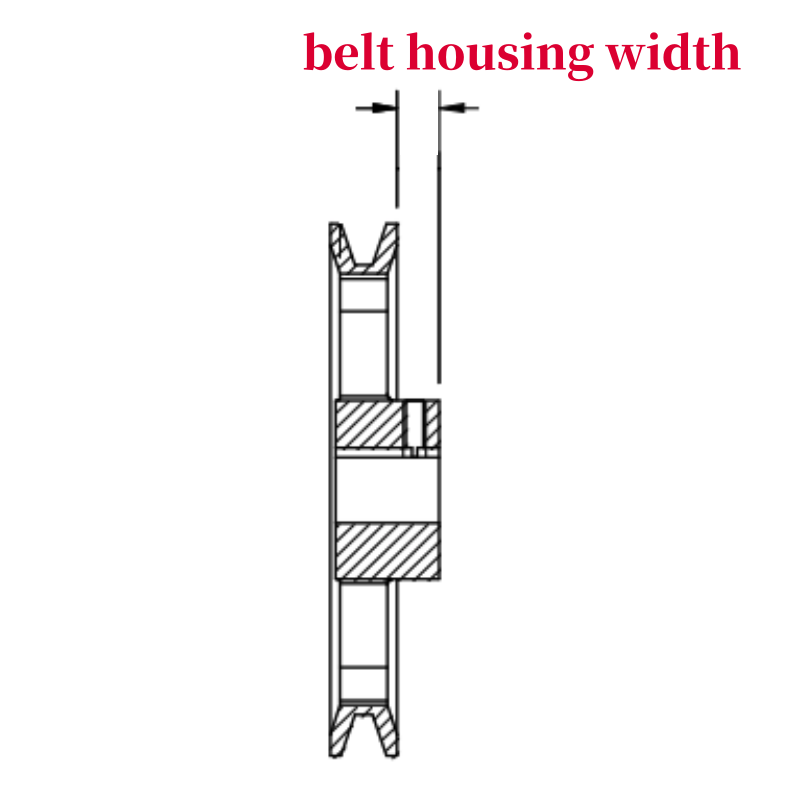

Measure the total width of the belt housing, where the belt runs in the pulley.

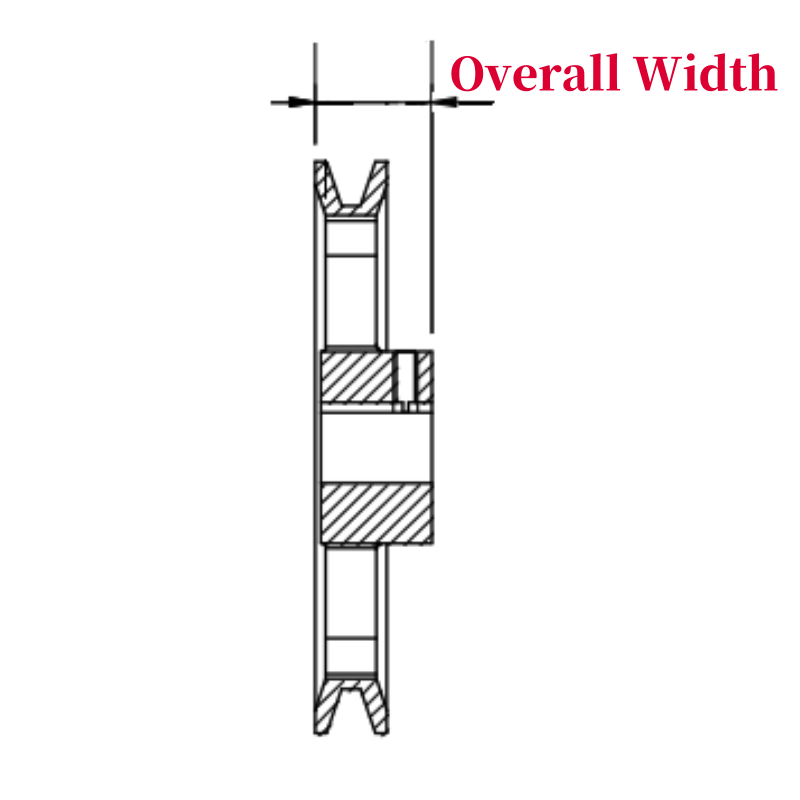

If the pulley has a hub that extends beyond the width of the "belt housing," it is often best practice to measure the extension of the hub.

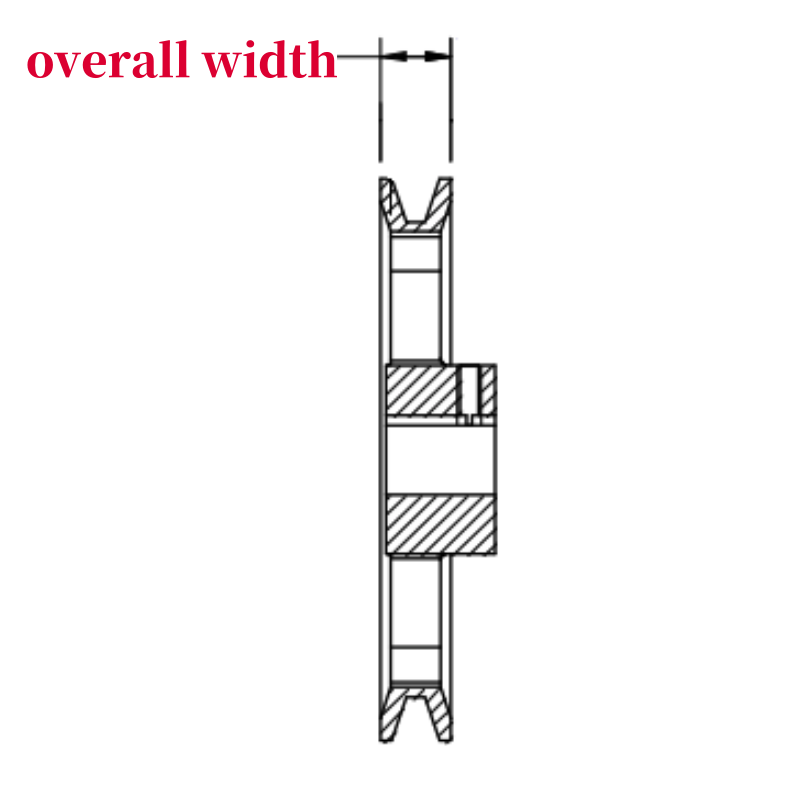

The final measurement is the entire overall width of the pulley. In most cases, this will specify the type or series of belts used.

V Belt Pulley Selection

V Belt Pulley Material

The material of a V-belt pulley significantly affects its performance and durability. Common materials include:

Cast Iron: Known for its strength and wear resistance, ideal for heavy-duty applications.

Steel: Offers high strength and is suitable for high-speed applications.

Aluminum: Lightweight and corrosion-resistant, suitable for applications where weight is a concern.

Selecting the right material depends on the specific requirements of the application, including load, speed, and environmental conditions.

V Belt Pulley Design Considerations

When designing or selecting a V belt pulley, several factors need to be considered:

Diameter: The diameter affects the speed ratio and torque transmission.

Width and Groove Angle: Proper width and groove angle ensure optimal belt grip and performance.

Alignment and Tension: Proper alignment and tension are crucial for minimizing wear and maximizing efficiency.

Load Capacity and Speed Rating: The pulley must be capable of handling the expected load and operating speed.

V Belt Pulley Application

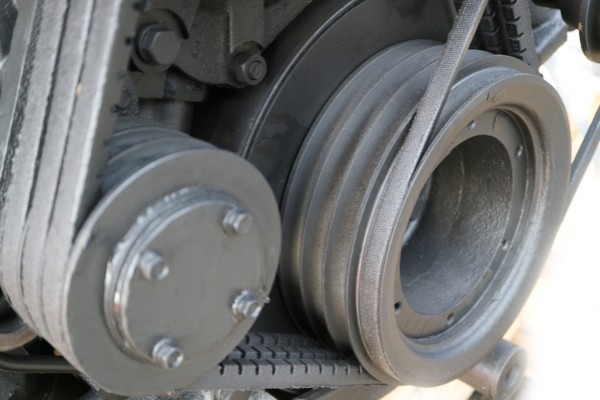

Automotive Industry:

Used in engines to drive components such as alternators, water pumps, and air conditioning compressors.

Agricultural Machinery:

Essential in tractors, combine harvesters, and other farming equipment.

Industrial Machinery and Equipment:

Commonly found in conveyor systems, compressors, and machine tools.

HVAC Systems:

Used in fans, blowers, and other heating, ventilation, and air conditioning equipment.

V Belt Pulley Maintenance

Regular maintenance is essential to ensure the longevity and efficiency of V belt pulleys. Key maintenance tips include:

✔ Regular Inspection: Check for signs of wear, cracks, and misalignment.

✔ Proper Tensioning: Ensure the belt tension is within the recommended range to prevent slippage and excessive wear.

✔ Alignment Checks: Regularly check and adjust pulley alignment to prevent uneven wear and potential belt failure. Common issues such as belt slippage, noise, and vibration can often be resolved by adjusting tension, realigning pulleys, or replacing worn belts.

V Belt Pulley Advantage

V belt pulleys offer several advantages that make them a popular choice in various industries:

High Power Transmission Efficiency:

The V-shaped groove provides excellent grip, reducing slippage and increasing power transmission efficiency.

Ability to Handle Misalignment:

V belts can tolerate slight misalignments between the pulleys, reducing the need for precise alignment.

Cost-Effectiveness and Ease of Installation:

V belt systems are relatively inexpensive and easy to install and replace.

Low Maintenance Requirements:

With proper installation and maintenance, V belt pulleys require minimal upkeep, offering long service life.

V belt pulleys are indispensable components in many mechanical systems, offering efficient power transmission and reliable performance. Understanding their design, operation, and maintenance is crucial for selecting the right pulley for your needs. As technology advances, we can expect further improvements in the performance and versatility of V belt pulleys, ensuring they remain a vital part of industrial and mechanical applications.

CTS | V-Belt Pulley Supplier

CTS®-ChinaTransmissionS is a professional v-belt pulley manufacturer in the power transmission industry. We can provide solid bore and taper bore SPA, SPB, SPC, and SPZ V-belt pulleys. In addition, we manufacture timing belt pulleys and can provide customized service for you.

If you have any questions about industrial transmission chains, please contact us.