What Is a Weld-On Hub?

Weld-on hubs are mechanical components used to securely attach power transmission parts, such as sprockets, pulleys, and gears to shafts. Weld-on hubs are designed to be welded onto a mating component, creating a strong and permanent connection that can handle heavy loads and rotational forces. These hubs are commonly made from steel or cast iron, ensuring durability and resistance to wear.

Weld-On Hubs Function in Mechanical Power Transmission

Weld-on hubs serve as an intermediary between a rotating shaft and a mechanical component. Here's how they work:

1) Welding to a Component – The hub is welded to a sprocket, pulley, or gear, forming a rigid connection.

2) Fitting onto a Shaft – The hub is then mounted onto a shaft, often using a keyway and set screw for additional security.

3) Transmitting Torque – The welded hub ensures efficient torque transmission, allowing smooth and reliable operation in various machinery applications.

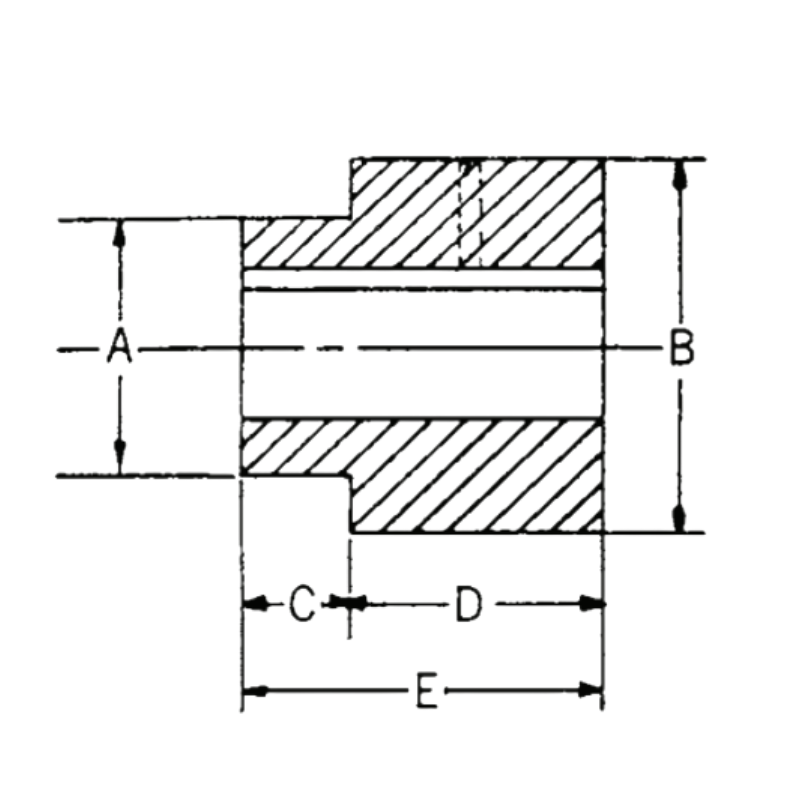

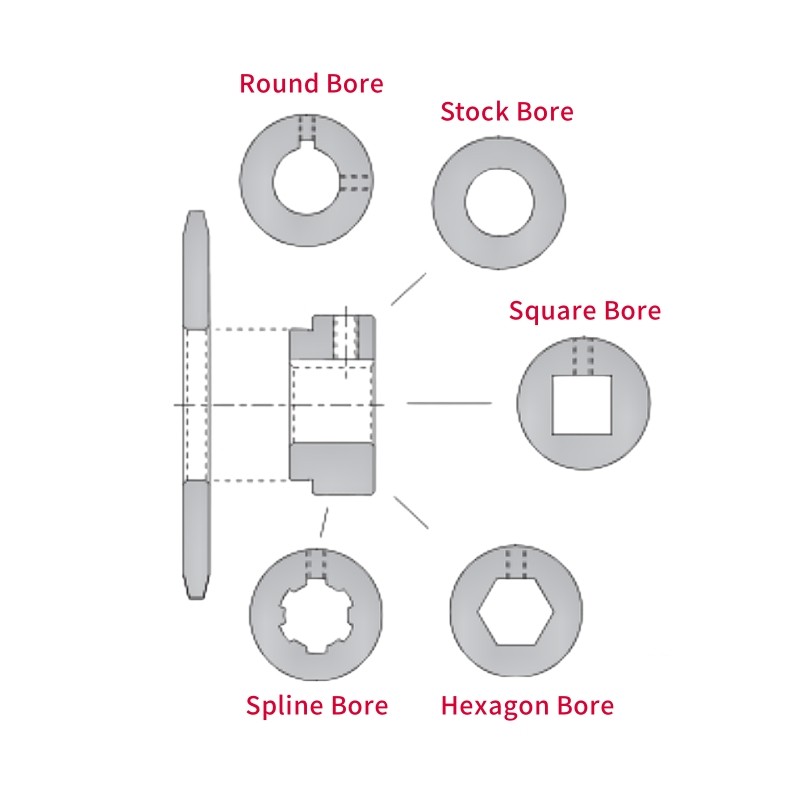

Weld-On Hubs Size

We can provide high-quality, precision-machined V, W, Y, and X series weld-on hubs. Available in round, stock, square, hexagon, and spline bore weld-on hubs.

Differences Between Weld-On Hubs and Other Types of Hubs

| Feature | |||

| Attachment Method | Welded directly to component | Use a taper bushing | Uses a split bushing with bolts |

| Strength | Very strong, permanent | Secure but removable | Secure and easily replaceable |

| Ease of Installation | Requires welding | Requires bolting and alignment | Quick installation and removal |

Common Use Cases | Heavy-duty applications, permanent setups | Moderate-duty, flexible setups | Application requiring frequent component replacement |

Weld-on hubs are preferred in applications with a permanent and extremely strong connection. While other hubs provide flexibility for removal and replacement, weld-on hubs ensure that components remain securely attached under high-load and high-speed conditions.

Applications of Weld-On Hubs

One of the biggest advantages of weld-on hubs is their compatibility with multiple power transmission components:

✅ Sprockets – Used in chain-driven systems to drive machinery.

✅ V-Belt Pulleys – Help transmit power using V-belts in motor-driven applications.

✅ Gears – Provide torque transmission in mechanical gear systems.

CTS | Power Transmission Parts Supplier

CTS®-ChinaTransmissionS is a professional power transmission products supplier with over 14 years in the power transmission industry.

If you have any questions about roller chains, please contact us. We offer various power transmission products: