Timing Belt Pulley Bore Types & Tooth Profiles for Different Applications

Timing belt pulleys come in various bore types and tooth profiles, each suited for specific power transmission needs. Selecting the right combination ensures efficiency, minimal slippage, and long-lasting performance in applications such as automotive, industrial machinery, automation, and robotics.

Bore Types for Timing Belt Pulleys

Round Bore Timing Pulley

A standard cylindrical bore.

Best for: Basic applications where no extra holding mechanism is needed.

Keyway Bore Timing Pulley

Includes a keyway slot for secure fitting.

Best for: Applications requiring high torque transfer.

Double Groove Timing Pulley

A timing pulley with flanges on both sides to prevent the timing belt from slipping off.

Best for: Applications requiring precise belt tracking and alignment.

Thread Bore Timing Pulley

Has internal threading for attachment using bolts.

Best for: Special applications where secure mounting is required.

Hexagon Bore Timing Pulley

Features a six-sided bore for fitting onto hexagonal shafts.

Best for: High-torque applications with precise shaft fitting.

D Bore Timing Pulley

A cylindrical bore with a flat side to prevent rotation.

Best for: Applications where anti-rotation is needed.

Idler Bearing Timing Pulley

A pulley designed for tensioning timing belts without a drive shaft.

Best for: Maintaining belt tension.

Taper Bush Timing Pulley

Uses a taper lock bushing for easy installation and removal.

Best for: High-power transmission applications.

Tooth Profiles for Timing Belt Pulleys

Arc Toothed

HTD 3M, 5M 8M 14M 20M Timing Pulley

Best for: High-torque applications.

Common Uses: Heavy-duty machinery, high-load applications.

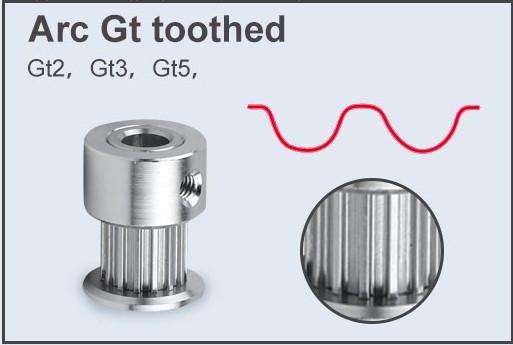

Arc Gt Toothed

Gt2, Gt3, Gt5 Timing Pulley

Best for: Precision applications requiring reduced backlash.

Common Uses: CNC machines, robotics.

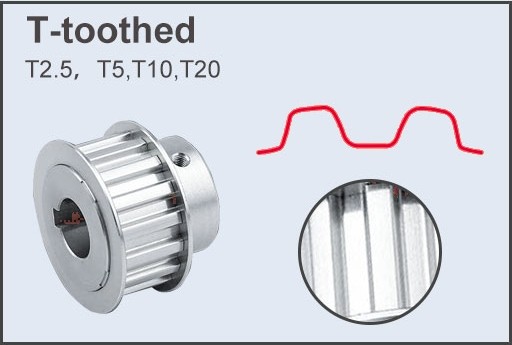

T-Toothed

T2.5, T5, T10, T20 Timing Pulley

Best for: Moderate torque applications.

Common Uses: Packaging machines, conveyors, automation.

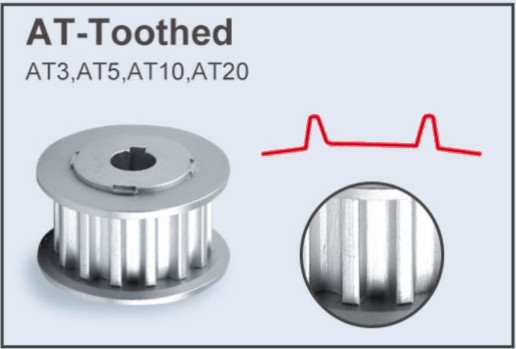

AT-Toothed

AT3, AT5, AT10, AT20 Timing Pulley

Best for: Higher load capacities and positioning accuracy.

Common Uses: Precision machinery, printing equipment.

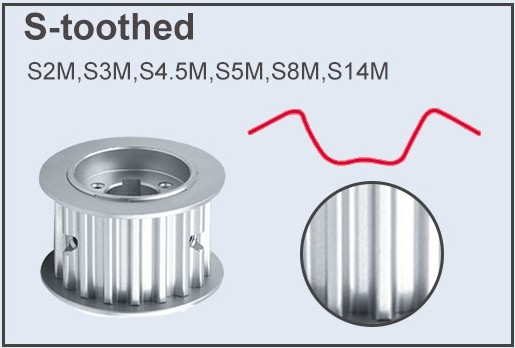

S-Toothed

S2M, S3M, S4.5M, S5M, S8M, S14M Timing Pulley

Best for: Noise-sensitive applications.

Common Uses: Medical equipment, electric vehicles.

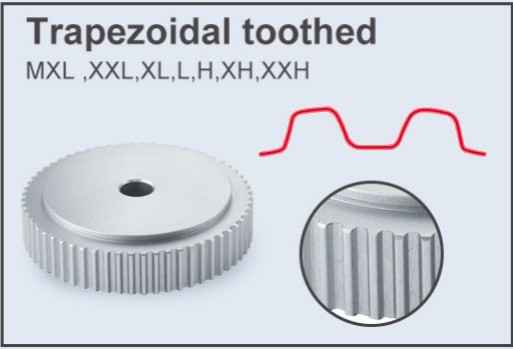

Trapezoidal-Toothed

MXL, XXL, XL, L, H, XH, XXH Timing Pulley

Best for: Low to moderate torque applications.

Common Uses: Light-duty automation, 3D printers.

Choosing the Right Bore Type & Tooth Profile Pulley

| Application | Recommend Timing Pulley Bore Type | Recommend Timing Pulley Tooth Profile | Special Features |

| Industrial Automation | Keyway bore, Taper bore timing pulley | T10, HTD 5M... | High-torque, precision motion control |

| Heavy Machinery | Taper bore, Hexagon bore timing pulley | Arc toothed, At20... | Strong load-bearing capacity |

| Robotics | D bore, Set screw bore timing pulley | Arc gt, At5... | Smooth operation, low backlash |

Automotive Engines | Keyway bore, Taper bore timing pulley | HTD 14M, Arc toothed... | High-speed performance |

Conveyor System | Taper bore, Double flange timing pulley | HTD 5M, T10... | Prevents belt misalignment |

Precision Equipment | Set screw bore, Idler timing pulley | S-toothed, Gt2... | Silent operation, minimal vibration |

CTS Timing Belt Pulley Selection

Different types and materials of timing pulleys have different characteristics. Choose the most appropriate timing pulley type and material of timing belt pulleys according to the characteristics of the applications.

Whether you prioritize cost-efficiency or precision, selecting the appropriate timing pulley is key to ensuring optimal system performance. Contact us today for professional guidance in selecting the best timing belt pulley for your project!