Key Indicators for Identifying a Quality Roller Chain Supplier

When selecting a roller chain supplier, the quality of the roller chains directly impacts the performance and longevity of your machinery.

A high-quality supplier not only provides reliable products but also contributes to smoother operations, fewer maintenance issues, and reduced downtime. In this blog, we’ll explore the key indicators to help you identify a trusted, high-quality roller chain supplier.

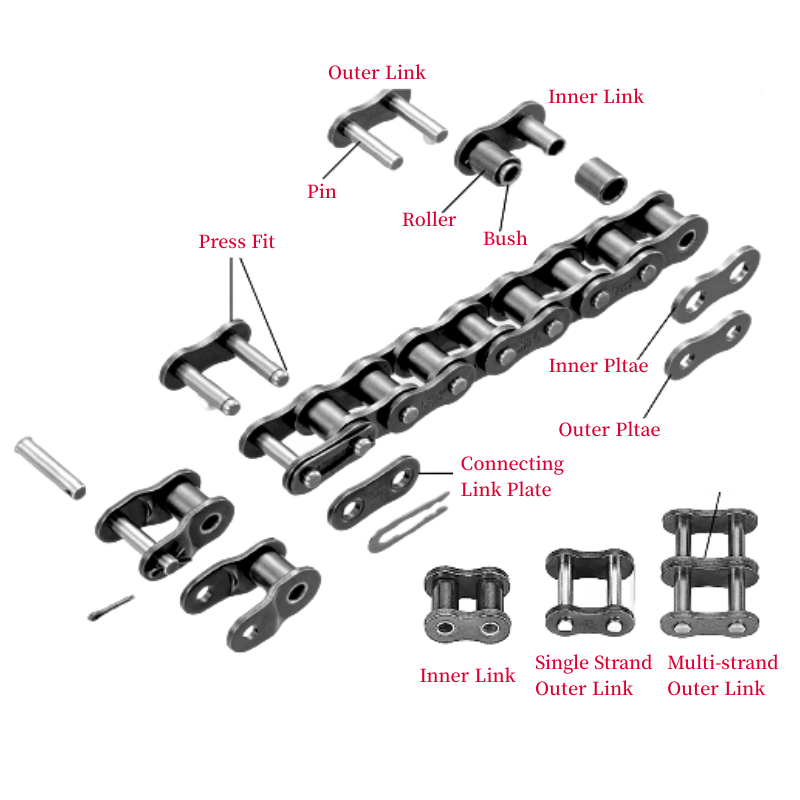

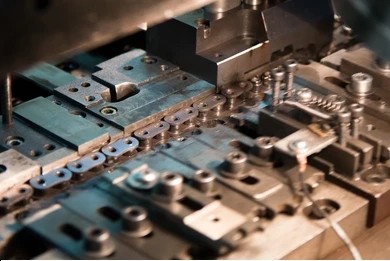

High-Precision Manufacturing Process

One of the first indicators of a quality roller chain supplier is its manufacturing process. Roller chain suppliers that employ advanced, high-precision machinery ensure that every component of the chain—the links, rollers, or pins—is consistently manufactured to meet strict specifications. Poor-quality roller chains often result from inconsistent cutting, forming, or assembly, leading to defects that can cause chain failure in critical applications.

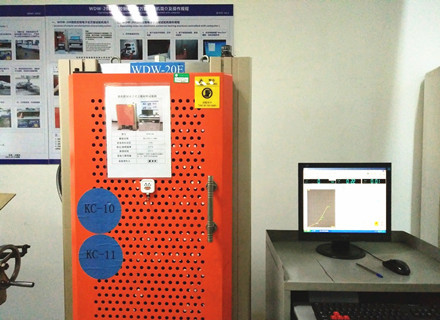

Heat Treatment and Material Strength

A key factor in determining the durability of a roller chain is the supplier’s heat treatment process. Proper heat treatment enhances the chain’s strength, load-bearing capacity, and resistance to wear. For example, roller chains should undergo hardness testing to ensure they meet specific standards.

Assembly and Dimensional Accuracy

The assembly process is another crucial area to examine when assessing a roller chain supplier. High-quality roller chain suppliers ensure that every component fits perfectly together, resulting in better operational stability and less noise during use. Dimensional accuracy plays a huge role in roller chain performance. Inconsistent assembly can lead to mechanical inefficiencies and higher wear.

Surface Treatment and Corrosion Resistance

Good surface treatment provides an additional layer of protection against corrosion, extending the lifespan of roller chains, especially in harsh operating environments. Quality roller chain suppliers often use treatments like electroplating or specific coatings to improve corrosion resistance. Roller chains with smooth, evenly treated surfaces are less likely to rust and wear prematurely.

Testing and Quality Control

Rigorous testing and quality control are essential for ensuring that roller chains meet performance standards. Roller chain suppliers that provide tensile strength tests, fatigue resistance evaluations, and other quality assurance measures are more likely to deliver reliable products. Partnering with suppliers that prioritize testing reduces the risk of mechanical failures.

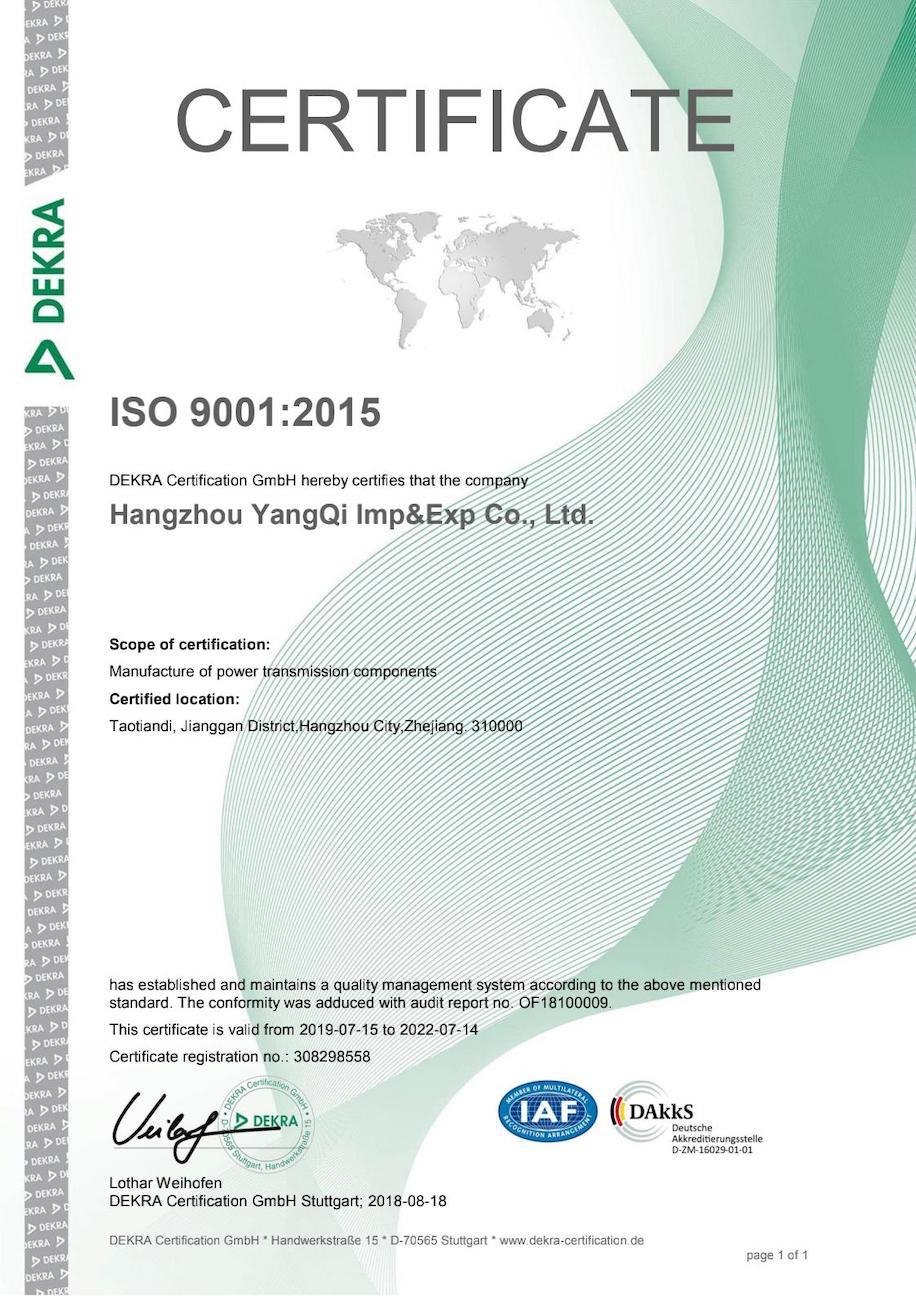

Supplier Reputation and Certifications

Roller chain supplier’s reputation in the industry is a strong indicator of their commitment to quality. Reputable roller chain suppliers often adhere to internationally recognized standards, such as ISO certifications, and provide extensive after-sales support. Checking customer reviews, industry feedback, and certifications can give you confidence in the roller chain supplier’s ability to deliver consistently.

CTS - High Quality Roller Chain Supplier

CTS® Roller Chain is an industry-leading roller chain supplier with excellent customer service. We have been providing industrial chain solutions for 14 years. We offer a wide range of industrial chain options: roller chains, conveyor chains, stainless steel chains, heavy-duty roller chains, double-pitch roller chains, roller chain attachments, etc. We also support roller chain customization services. We believe that every customer deserves our full attention, and you can depend on our professional team members to help you find the right product.

CTS-ChinaTransmissionS is a professional roller chain manufacturer, any questions let us know, Contact us, and our technicians will be happy to help you!