How To Identify Your Roller Chain?

Roller chains are essential in various industrial and mechanical applications, but identifying the correct chain type and size is crucial for proper replacement and maintenance. This guide will cover the key aspects of roller chain identification, including measurements, markings, and chain standards.

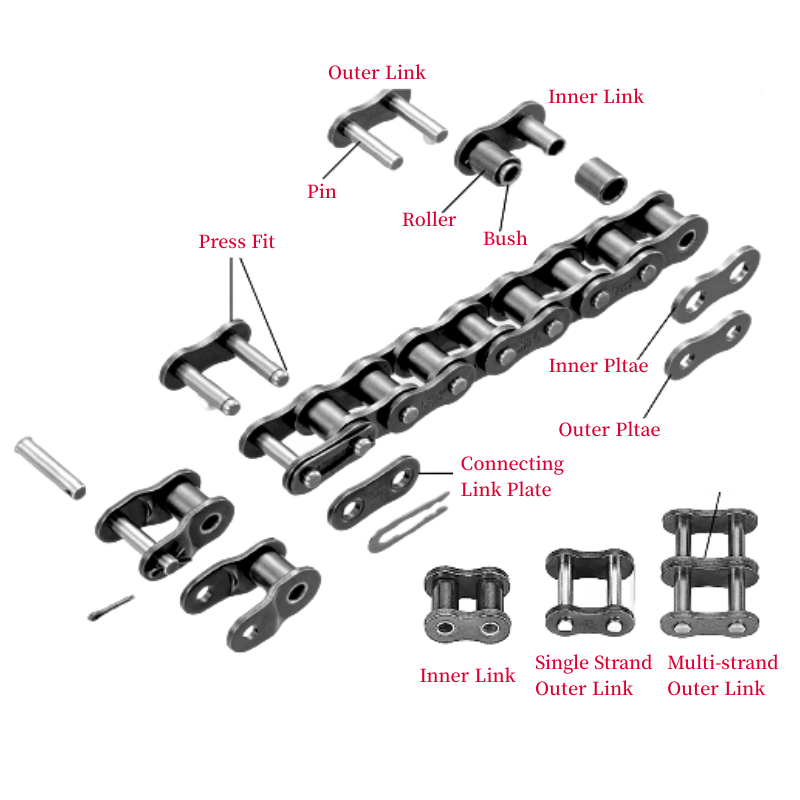

Roller Chain Components

Roller Chains Parts

✅ Chain Pitch: The distance between the centers of two adjacent pins.

✅ Chain Roller Diameter: The outer diameter of the roller.

✅ Inner Width: The distance between the inner plates of the chain.

✅ Chain Pin Diameter: The thickness of the pins that connect the links.

✅ Chain Plate Thickness: The thickness of the outer and inner plates.

✅ Overall Width: The total width of the chain including the pinheads.

Each of these measurements helps determine the exact type of roller chain you have.

Identifying the Chain Size Using a Roller Chain Chart

Different roller chains follow standard sizes based on ANSI (American National Standards Institute) and ISO (International Organization for Standardization) specifications. The most common standard chains include:

ANSI Standard Roller Chains: Sizes range from #25 to #240, where the pitch increases with the number.

Metric Roller Chains: Used in Europe and Asia, following ISO 606 standards.

Identifying Specialty Roller Chains

If your chain doesn't match standard sizes, it may be a specialty chain:

Double Strand Roller Chain & Triple Strand Roller Chains: Used for heavy-duty applications.

Leaf Chains: Typically found in forklift applications.

Nickel-plated or Stainless Steel Roller Chains: Designed for corrosion resistance.

Conveyor Chains: Often include attachments for material handling.

Comparing your chain's specifications with manufacturer charts can help confirm the exact type. If you can not identify your chain type, you can contact our technicians to help you figure it out.

Measuring Your Chain for Accurate Identification

How To Measure Roller Chains?

If no markings are visible, measure the chain using a caliper or ruler:

Measure pitch from pin center to pin center.

Check roller diameter using calipers.

Determine the inner width between inner plates.

Count the number of links per foot to confirm chain size.

Use these measurements to compare with ANSI or ISO standard chain tables.

CTS | Professional Roller Chain Manufacturer

CTS®-ChinaTransmissionS is a professional roller chain supplier with over 14 years in the power transmission industry.

As a professional roller chain supplier, our experienced technical team always learns the latest manufacturing technology. It would be better for you to build long-term and stable cooperation with us, and we can provide priority service and fast response for the first time.

We offer various industrial chain options: roller chains, conveyor chains, stainless steel chains, heavy-duty roller chains, double-pitch roller chains, roller chain attachments, etc.

If you want to replace your roller chains or have any questions about roller chains, please contact us.

Roller Chain FAQs

How do I know if my roller chain needs to be replaced?

If the roller chain has elongated by more than 2%, has visible cracks, or stiff links, replace it.

Are ANSI and ISO roller chains interchangeable?

No, ANSI roller chains use inch-based measurements, while ISO roller chains use metric dimensions. Always check compatibility.