Comprehensive Guide to Sugar Cane Harvester Chains

CA Type Agricultural Chain

Sugar cane harvesting demands tough, reliable components, and sugarcane harvester chains are critical. This guide explores the types, features, applications, and maintenance of sugar cane harvester chains, ensuring your harvesting process runs smoothly and efficiently.

Sugar Cane Harvester Chain Dimension

Customized Sugar Cane Harvester Chain

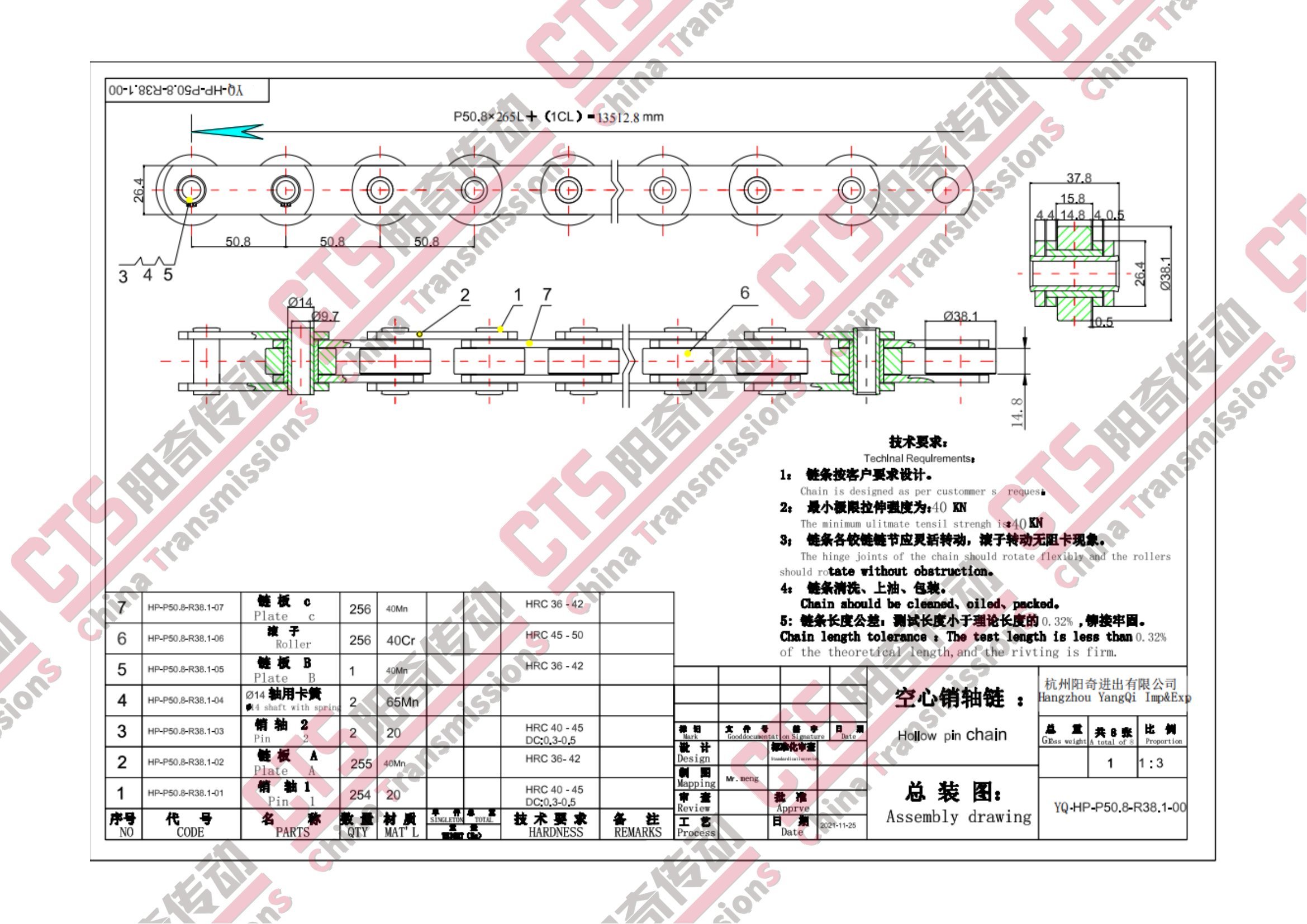

In addition to standard sugarcane harvester chains, we can also provide customized sugarcane harvester mill chains for your specific application needs.

Key Features of Sugarcane Harvester Chains

High Durability

Sugar cane harvester mill chains are manufactured from high-grade steel and often undergo specialized heat treatment processes to enhance strength and wear resistance. This ensures cane harvester mill chain can endure the tough conditions of sugarcane fields.

Corrosion Resistance

Many sugarcane harvester chains are coated or treated to resist corrosion, which is essential given their exposure to moisture and harsh environments.

Hollow Pin Design

Some suagr mill chains feature a hollow pin design, allowing for easy customization and attachment of specialized parts. This design enhances the flexibility of the harvesting system.

Standardized Sizes

Sugarcane chain sizes like CA732, CA734, and others are widely used in sugarcane harvesters, offering compatibility with various machinery models.

Why Choose CTS® Sugarcane Harvester Mill Chain

✔ Improved material and heat treatment to increase tensile strength

✔ Improved pins to increase wear resistance

✔ Improvements to increase roller wear life

✔ Hollow pins are fully peripheral riveted to enhance side-plate security. Accurately positioned side plates

✔ Chains completely immersed in a specially formulated lubricant to provide protection

CTS®-ChinaTransmissionS is a professional agricultural chain manufacturer in the power transmission industry. As an experienced agricultural chain supplier, we manufacture chains with high-quality steel material. Besides standard agricultural chains, we can also provide customized agricultural chains for your application.

We offer a wide range of industrial transmission chain options: drop forged rivet-less chains, welded steel chains, 81X lumber conveyor chains, roller chains, conveyor chains, heavy-duty roller chains, etc.

If you have any questions about industrial transmission chains, please contact us to help you.

Professional Chain Manufacturers

With years of experience, we understand the needs of your application.

Various chain attachments

Attachments are commonly used for agricultural roller chains, we can supply complete chain attachment options.

High Standards of Quality Control

Our rigorous quality checks ensure every chain meets the highest standards.

Tips for Agricultural Chains Maintain

Regular Lubrication: Reduces friction and prevents wear.

Inspect for Damage: Check for signs of elongation or broken links.

Keep Clean: Remove debris and dirt after each use.

Store Properly: Avoid exposure to moisture when not in use

FAQs

Can harvester chains be customized for different Sugar Cane Harvesters?

Yes, we can manufacture sugarcane mill chains that can be tailored with specific dimensions and attachments to suit various harvesters.

What are the signs of chain wear and tear?

Look for elongation, rust, and uneven wear on the links and rollers.