ANSI Roller Chain

ANSI Roller Chain

Roller chains are essential components in many mechanical systems, providing efficient and reliable power transmission. ANSI roller chains, regulated by the American National Standards Institute (ANSI), are particularly well-regarded for their strict dimensional and performance criteria, ensuring compatibility and durability across various applications.

The ANSI B29.1 standard covers 14 different sizes of RS Roller Chains, helping manufacturers produce roller chains that can be used interchangeably with sprockets from other vendors, simplifying maintenance, and enhancing equipment compatibility.

Types of ANSI Roller Chain

Single-Strand Roller Chains:

Commonly used in basic power transmission applications, available in chain sizes: ANSI RS25, RS35, RS40, RS41, RS50, RS60, RS80, RS100, RS120, RS140, RS160, RS180, RS200 and RS240.

Double-Strand Roller Chains:

Offer higher load capacity, suitable for heavier machinery.

Triple-Strand and Quadruple-Strand Roller Chains:

Used in high-power applications where single or double-strand chains are insufficient.

Specialty Chains:

Include heavy-duty and double-pitch roller chains for specific industrial uses.

ANSI Roller Chain Pitch Size

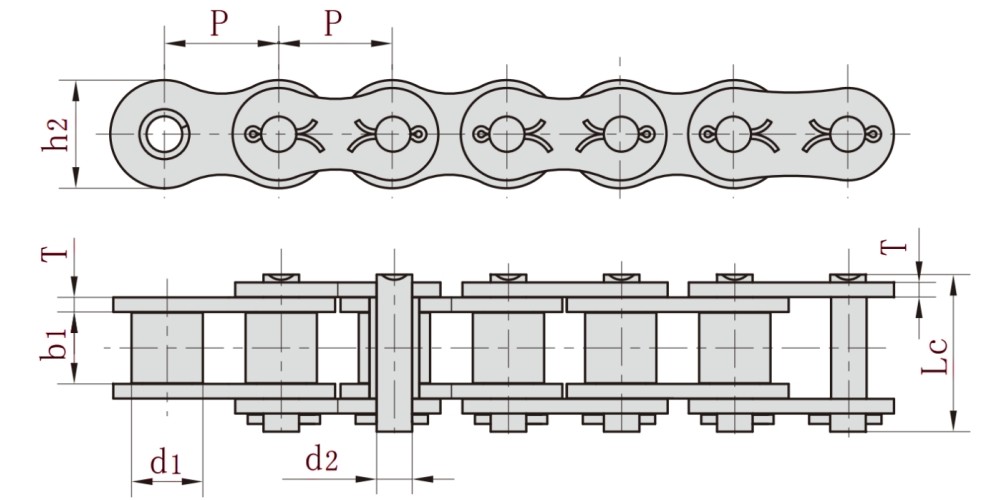

ANSI Roller Chain Dimension

✔ Pitch (P):

Distance between roller centers.

✔ Inner Width (b1):

Distance between inner plates.

✔ Roller Diameter (d1):

Diameter of the rollers.

✔ Plate Height (h2) and Thickness (T):

Dimensions of the chain plates.

✔ Pin Diameter (d2)

The diameter of the connecting pins.

ANSI Simplex Roller Chain Dimension

ANSI Duplex Roller Chain Dimension

ANSI Triplex Roller Chain Dimension

Choosing the Right ANSI Roller Chain

Selecting the appropriate roller chain involves considering factors like load capacity, environmental conditions, and compatibility with existing sprockets. Accurate measurement and identification of the roller chain size are essential steps in this process.

Proper maintenance is key to extending the life of roller chains. Regular lubrication, tension checks, and timely replacement of worn-out components can prevent common issues like chain elongation and sprocket wear. Understanding and troubleshooting these issues can ensure smooth and reliable operation