Industrial Chain and Sprocket Manufacturer

Wholesale Supply

For You

150,000 Products

Complete variety

More than 14 Years

Trust and experience

ANSI, ISO

Satisfaction guaranteed

- Sprocket Standard

- Metric Sprocket

- ANSI Sprocket

- KANA Sprocket

- Sprocket Type

- Standard

- Finished Bore

- Taper Bore

- Idler Sprocket

- With Split Bushing

- With QD Bushing

- DS (Double Single)

- Double Pitch

- Hub Type

- A

- B

- C

- Row

- Simplex

- Duplex

- Triplex

- Bore Diameter

- 4

- 5

- 6

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 18

- 19

- 20

- 22

- 23

- 21

- 24

- 25

- 26

- 28

- 30

- 32

- 35

- 38

- 40

- 41

- 42

- 43

- 45

- 46

- 47

- 48

- 49

- 50

- 56

- 59

- 60

- 62

- 63

- 64

- 65

- 70

- 71

- 73

- 75

- 76

- 79

- 80

- 87

- 90

- 95

- 100

- 102

- 105

- 108

- 110

- 120

- 140

- 150

- 159

- 160

- 175

- 215

- 260

- 1/4''

- 3/8''

- 1/2''

- 19/32''

- 5/8''

- 23/32''

- 3/4''

- 7/8''

- 15/16''

- 1''

- 1-1/8''

- 1-3/16''

- 1-1/4''

- 1-5/16''

- 1-3/8''

- 1-7/16''

- 1-1/2''

- 1-5/8''

- 1-11/16''

- 1-3/4''

- 1-7/8"

- 2''

- 2-3/16"

- 2 1/4"

- 2-7/16"

- 2 1/2"

- 2 3/8"

- 2-5/8"

- 2 11/16"

- 2 13/16"

- 2-15/16"

- 3"

- 3 1/2"

- 3 5/8"

- 3 3/4"

- 3 15/16"

- 4 3/16"

- 4 1/4"

- 4 1/2"

- 4 7/16"

- 5 1/2"

- 5 7/8"

- 6"

- 1 13/16"

- 2 1/16"

- 2 3/4"

- 3 1/8"

- 3 1/4"

- 3 7/8"

- 3 1/16"

- 5 1/4"

- Number of Teeth

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

- 62

- 64

- 65

- 66

- 68

- 70

- 72

- 75

- 76

- 78

- 80

- 84

- 85

- 90

- 95

- 96

- 100

- 102

- 110

- 112

- 114

- 120

- 125

- Material

- Carbon Steel

- Stainless Steel

Sprockets

- What

- Products Type

- Select Products

- FAQ

- Application

- Why CTS

What is Industrial Chain Sprockets?

A chain sprocket is a rotating wheel with teeth that interact with roller chain sprockets or conveyor sprockets, enabling their movement in various applications. The specially designed teeth engage the chain gaps, securely pulling it as the sprocket rotates around a central shaft. This secure grip remains effective even in dirty or oily environments. Unlike gears, chain sprockets are exclusively designed to work with chains, not other sprockets or gears.

CTS® professionals have been focusing on producing and manufacturing chain sprockets for fourteen years and specialize in top-quality drive and conveyance components, power transmission parts, and custom-designed products. If you want to find a satisfactory roller chain sprocket solution as soon as possible, then you've come to the right place. We have the full range of industrial sprockets products, and our team is here to assist you in finding the ideal solution.

Chain Sprockets Resources

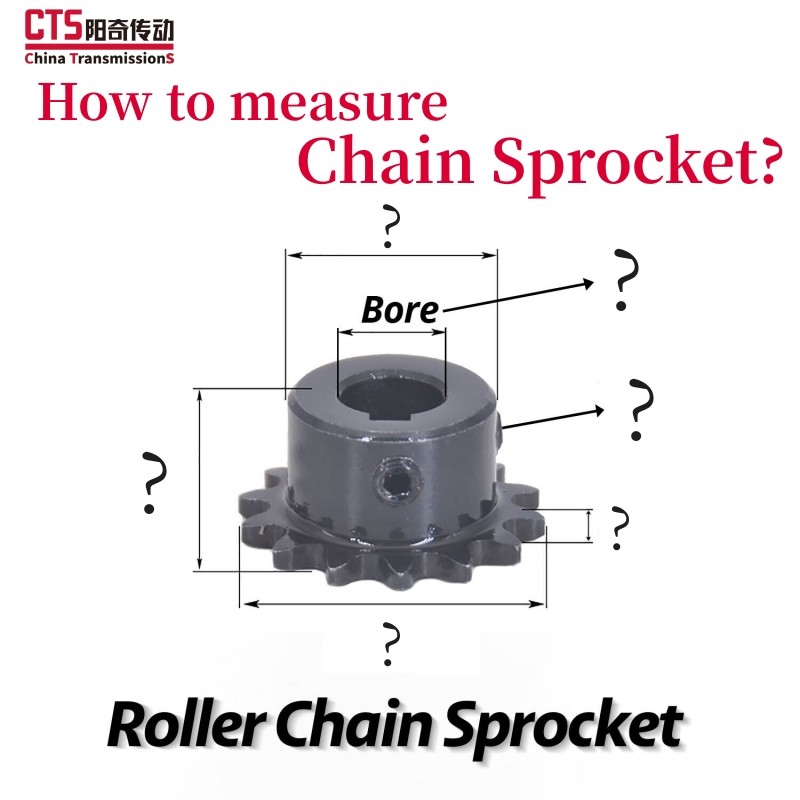

How to help quickly identify your chain sprocket, contact us for a quick response.

Chain Sprocket Wholesale

Chain Sprocket Type

Chain Sprocket Wholesale

Chain Sprocket By Chain Size

Chain Sprocket Wholesale

Chain Sprocket Selection

| Image | Sprockets | Description | In stock | More |

|---|---|---|---|---|

| ANSI #41A Plain Bore Stainless Steel Sprockets | #41A platewheel stainless steel sprockets are suitable for all roller chains according to A series | In Stock | |

| ANSI #41A Plain Bore Sprockets | #41A platewheel sprocket is an important part of the chain drive and is suitable for all roller chains according to A series | Available Now | |

| ANSI #35B Taper Bore Duplex Sprockets | #35B taper bore duplex sprockets are precision-engineered for optimal power transmission and industrial machinery. | In Stock | |

| ANSI #35B Taper Bore Sprockets | #35B taper bore sprockets are precision-engineered for optimal power transmission and industrial machinery. | Email/Call | |

| ANSI #35B Finished Bore Sprockets | #35B finished bore sprocket is an important part of the chain drive and suitable for all roller chains according to A series | In Stock | |

| ANSI #35B Plain Bore Triplex Stainless Steel Sprockets | #35B triplex stainless steel sprockets are suitable for triplex roller chain according to A series | In Stock | |

| ANSI #35B Plain Bore Triplex Sprockets | #35B triplex sprocket is an important part of the chain drive and is suitable for triplex roller chain according to A series | In Stock | |

| ANSI #35B Plain Bore Duplex Stainless Steel Sprockets | #35B duplex stainless steel sprockets are suitable for all duplex roller chain according to A series | In Stock | |

| ANSI #35B Plain Bore Duplex Sprockets | #35B duplex sprocket is an important part of the chain drive and is suitable for all duplex roller chain according to A series | Available Now | |

| ANSI #35B Plain Bore Stainless Steel Sprockets | #35B stainless steel sprocket is an important part of the chain drive and suitable for all roller chain according to A series | In Stock |

Chain Sprocket Resource

Chain Sprocket FAQ

Chain Sprocket Application

About CTS® Chain Sprocket

Professional Chain Sprocket Manufacturer

Your Trusted Partner In Custom Chain Sprocket Manufacturing

CTS's Commitment

High-quality materials and manufacturing:

We prioritize quality and customer satisfaction as our differentiators.

Pursuit of perfection:

We strive to be the “best” in all our actions.

Customer-centric approach:

We value our customers’ needs and treat them as our roadmap.

Continuous Innovation:

Research and development are core values for our growth and success.

Global Vision:

Transmit Force, Drive Future. We aspire to become a globally renowned company that drives a more sustainable future with high-quality industrial transmission products.

Ask CTS?

Having trouble finding the product you need? Send us an email with your question or message, and we'll quickly respond with tailored solutions. We're eager to hear from you! Expect top-notch precision, reliability, efficiency, and performance. Let's redefine excellence together.

- China's professional power transmission manufacturer

- We offer customized product services and free samples to meet our customers' needs.

- Some of our products are mass-produced and kept in stock, ready for immediate shipment.

- Contact CTS

- Name