Allowable chain extension due to wear

The Allowable chain extension due to wear

Depending on operating conditions such as load, temperature, contamination, corrosive environments, etc., the service life of the chain will vary. Since chains, like any mechanical element, are subject to wear, they should be visually inspected periodically. When inspecting, pay particular attention to signs of wear caused by elongation due to wear, chain tension, lubrication and tilting sprockets (so-called sprockets). Fault tracking effects

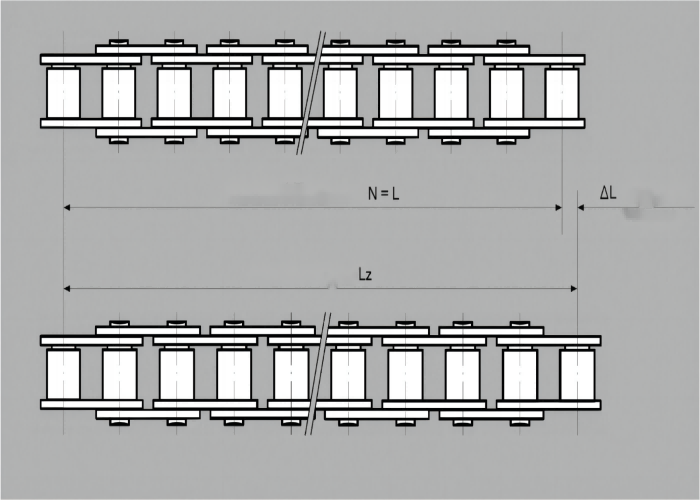

Chain Length measurement

ΔL =Lz-L/L*100%

The Length of chain: L =P(PITCH)*N(Link)

With manipulation, the chain becomes longer and can be measured with a simple measuring tape. Since we usually do not measure the load under industrial conditions, the length of the chain should be measured in sections of 30-40 knots for reliable results. The difference from the measurement under load is insignificant.

– ΔL ≥ 3 % for common gear units

– ΔL ≥ 2 % for efficient gear units

– ΔL ≥ 1% for special gearbox applications (e.g. positioning)

When visually inspecting, pay attention to the tightness of the chain, which has a major impact on its service life. It is assumed that the optimal tension should be 5% of the actual tension. In the absence of an automatic tensioner, the chain must be tensioned manually by moving one of the sprockets, or in the case of longer cogs, by shortening the chain.

In addition to the chain, the inspection should also include the sprockets. Remember that new chains on old sprockets wear faster.

Contact Us-Welcome To Send Us Inquiries!!!

Kimer Zheng

Hangzhou YangQi Imp&Exp Co.,Ltd

杭州阳奇进出口有限公司

Room 1310,Taotiandi Buliding 2,Jianggan District,Hangzhou City ,Zhejiang

Sales2@Chinatransmissions.Com

Mob/Whatsapp/wechat:+008618258831202

www.Chinatransmissions.Com