The Difference Between Sprockets and Gears

What's The Difference Between Sprockets and Gears?

The biggest difference between a sprocket and a gear is how each works on a functional level. Both tend to be grooved wheels used in machinery, and their basic appearance is often really similar, but how they operate and what exactly they do tend to be different. Generally, a gear is a toothed wheel designed to mesh with other gears and transmit movement to them, which can cause movement elsewhere. A sprocket, conversely, is a toothed wheel designed to engage and directly move a flexible indented, or perforated item, like a chain or belt. The applications of each are different as a result. Sprockets are most common when there's a moving belt or chain that is contained, as is commonly the case in bicycles, conveyor belts, and film projection reels. Gears are typically preferable in all other scenarios, cars and heavy machinery included. Not only are gears more universally useful, but they also aren't as likely to need repairs or re-fittings.

Sprockets and gears are both used to transmit power within machines or to move items by interlocking with them. A sprocket usually interacts directly with some part of the machinery at issue, however, whereas gears can and often do push against each other first, then use that collective movement to influence some larger mechanical process. Another way of expressing this is that sprockets have to work independently, but gears can use networks to build strength and precision. The difference is usually most noticeable when looking closely at the grooves or teeth of each.

What Is Chain Sprockets

A sprocket is a wheel with teeth designed to engage with a chain. Unlike gears, sprockets do not mesh directly with each other. Instead, the chain wraps around the sprocket, transmitting power between two rotating shafts.

Sprockets are widely used in:

✅ Bicycles and Motorcycles – for chain-driven transmission.

✅ Conveyor Systems – to move materials efficiently.

✅ Agricultural Machinery – such as combine harvesters and manure spreaders.

✅ Industrial Equipment – including lifting mechanisms and automation systems.

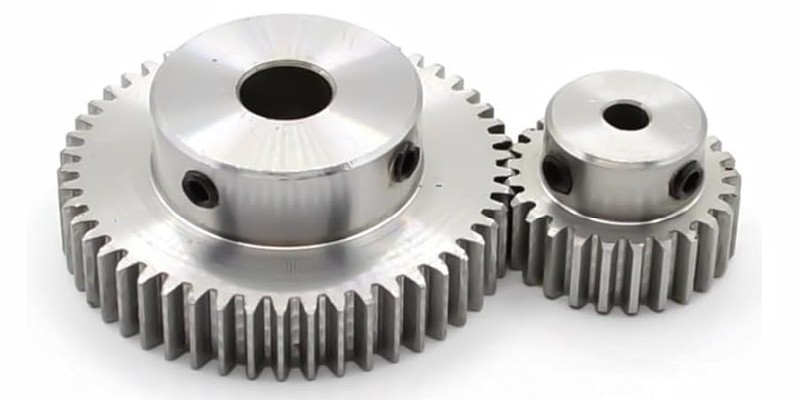

What Is Gears

A gear is a rotating machine part with teeth that mesh directly with another gear to transmit motion and torque. Unlike sprockets, gears do not require chains for power transmission.

Gears are widely used in:

✅ Automobiles – in gearboxes for speed and torque control.

✅ Industrial Machinery – in gear trains and reducers.

✅ Robotics – to provide precise motion control.

✅ Wind Turbines – to increase rotational speed for generators.

Key Differences Between Sprockets and Gears

| Features | Sprocket | Gear |

| Tooth Shape | Three-arc straight-line shape | Involute shape |

| Transmission Type | Works with chains | Direct meshing |

| Axle Configuration | Parallel shafts only | Parallel and non-parallel shafts |

Load Capacity | Suitable for lower loads | Handles higher torque and loads |

Speed | Better for low to modera speeds | Suitable for high-speed applications |

Precision | Less precision | High precision, minimal backlash |

Efficiency | Slight energy loss due to chain friction | More efficient due to contact |

Durability & Wear | Chain elongation over time, requires maintainance | More durable but need lubrication |

When to Use Sprockets vs. Gears

Use Sprockets If:

✅ The shaft centers are far apart (e.g., bicycles, conveyors).

✅ You need a lightweight and cost-effective solution.

✅ The system operates at moderate speeds and loads.

✅ Easy maintenance and replacement are priorities.

Use Gears If:

✅ High precision and efficiency are required (e.g., automotive gearboxes).

✅ The system needs to handle high torque.

✅ Compact design is necessary (e.g., industrial reducers).

✅ Noise and backlash should be minimized.

Chain Sprocket Types

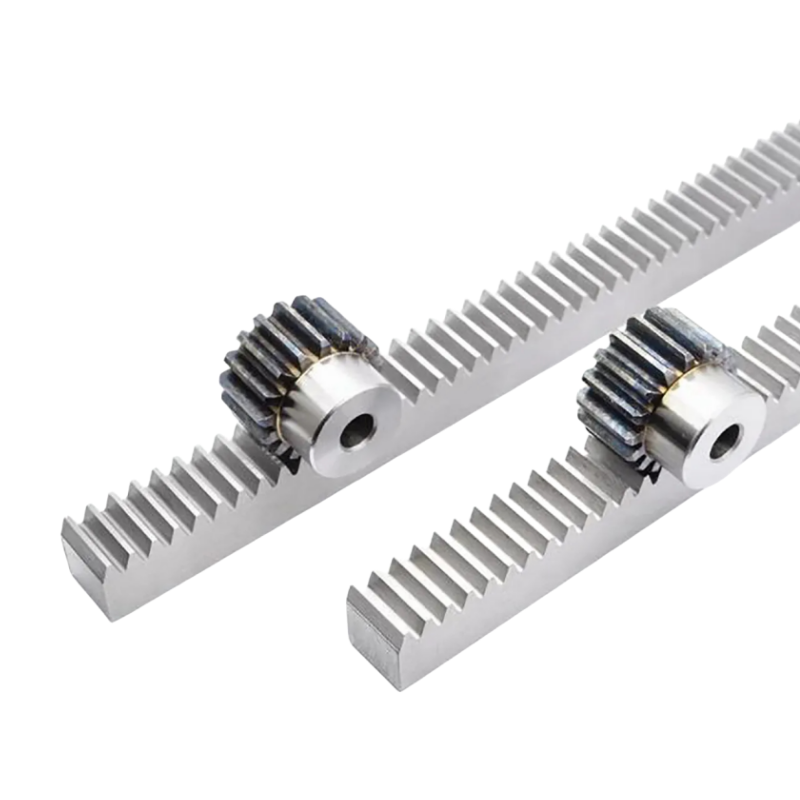

Gear & Rack Types

CTS® | Professional Sprockets and Gear Manufacturer

CTS® is a professional industrial sprocket and gear manufacturer with over 14 years of experience in the power transmission industry. We have our industrial sprocket factory and a professional technical team that can provide technical support and a responsive after-sales team after-sales team.

As a professional industrial sprocket manufacturer with mature industrial sprocket manufacturing technical, we can not only produce standard industrial sprockets(ANSI/DIN/KANA) but also customize industrial sprockets according to your specific needs.

If you have any questions about industrial sprockets and other transmission parts, please contact us to help you.