Different Types Of Sprockets

Industrial chain sprockets are toothed wheels designed to engage with the links of a roller chain to transmit mechanical power. It plays a crucial role in industrial machinery, conveyors, and agricultural equipment by ensuring smooth and efficient power transmission. Made from materials like carbon steel, stainless steel, or hardened alloys, chain sprockets come in various designs, including simplex, duplex, and triplex configurations, to accommodate different chain sizes and load requirements. Proper selection and maintenance of sprockets help reduce wear, improve efficiency, and extend the lifespan of both the chain and the sprocket.

A Finished Bore Sprocket is a sprocket that comes with a precisely machined bore, keyway, and set screws, ready for direct installation onto a shaft. Unlike plain bore sprockets, which require additional machining, finished bore sprockets are pre-made to fit standard shaft sizes, making installation quick and convenient. They are commonly used in power transmission systems where easy replacement and precise alignment are needed.

An idler sprocket is a free-spinning gear that doesn't transmit power like a drive sprocket. Instead, its primary role is to guide and support the chain. It ensures proper tension, alignment, and smooth operation in a mechanical system.

ANSI Idler Sprockets with Ball Bearing

Metric Idler Sprockets

Taper Lock sprockets are a popular sprocket designed for easy installation and secure connection to shafts. They feature a unique tapered bore design, which allows the sprocket to be mounted directly onto a shaft using a taper-lock bushing. This design eliminates the need for keyways or set screws, providing a secure and vibration-resistant fit. Taper Lock sprockets are commonly used in applications where quick assembly or disassembly is required, such as in conveyors, agricultural machinery, and industrial drives, offering improved reliability, ease of maintenance, and reduced downtime.

A Quick-Disconnect (QD) Sprocket is designed for easy installation and removal using a QD bushing. The sprocket has a tapered bore that fits onto a split QD bushing, which is secured to the shaft with bolts. This design ensures a tight, secure fit while allowing for quick replacement or adjustment without extensive disassembly. QD sprockets are commonly used in industrial power transmission systems, conveyors, and machinery where easy maintenance and flexibility are important.

A Double Single Sprocket is a special type of sprocket designed to accommodate two separate single-strand roller chains. It has two sets of teeth, each spaced apart to allow independent operation of both chains. This design is commonly used in conveyor systems and mechanical applications where two parallel chains need to run on the same shaft while maintaining separate movements. It helps improve efficiency and reduces the need for additional components in dual-chain systems.

A double-pitch sprocket is designed for use with double-pitch roller chains, which have twice the pitch of standard roller chains. These sprockets typically have larger tooth spacing and are commonly used in low-speed, light-load applications such as conveyors and packaging systems. They can come in either standard tooth profiles or with special "carrier" rollers for better chain engagement and reduced wear. Double-pitch sprockets provide a cost-effective solution for applications requiring longer chain life and smooth operation.

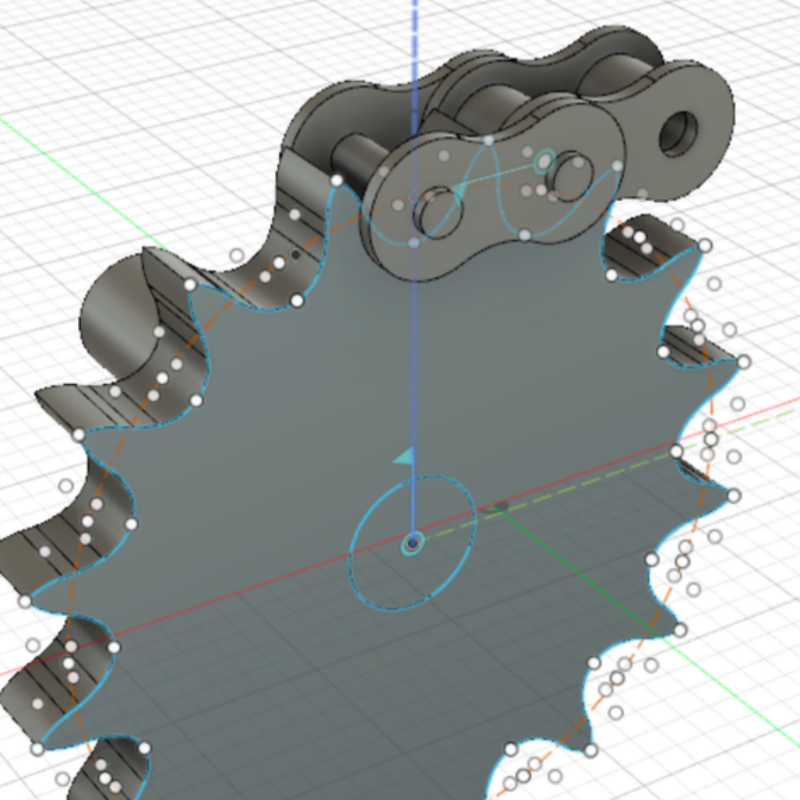

As a professional industrial chain and sprocket manufacturer, we can supply standard chain sprockets but also custom chain sprockets for you. Before ordering custom sprockets, you can confirm the sprocket material, pitch, size, bore type, hub type, teeth number, surface treatment, special features, and other details with us. Our experienced technicians will then create a chain sprocket drawing for you to check.

CTS® | Professional Industrial Sprocket Manufacturer

CTS® is a professional industrial sprocket manufacturer with over 14 years of experience in the power transmission industry. We have our own industrial sprocket factory and a professional technical team that can provide technical support and a responsive after-sales team after-sales team.

As a professional industrial sprocket manufacturer with mature industrial sprocket manufacturing technical, we can not only produce standard industrial sprockets(ANSI/DIN/KANA) but also customize industrial sprockets according to your specific needs.

If you have any questions about industrial sprockets and other transmission parts, please contact us to help you.

Industrial Sprocket CAD

CNC Machining

Customized Sprockets

Customers Good Review