How can I prevent conveyor sprockets from clogging?

How can I prevent conveyor sprockets from clogging?

The type of material your conveyor is moving could be causing your sprockets a problem, especially if it’s mixed with some moisture.

Over the years we’ve been called in to take a look at sprockets that are wearing prematurely in applications from infeed conveyors in sawmills to wet ash conveyors in biomass plants.

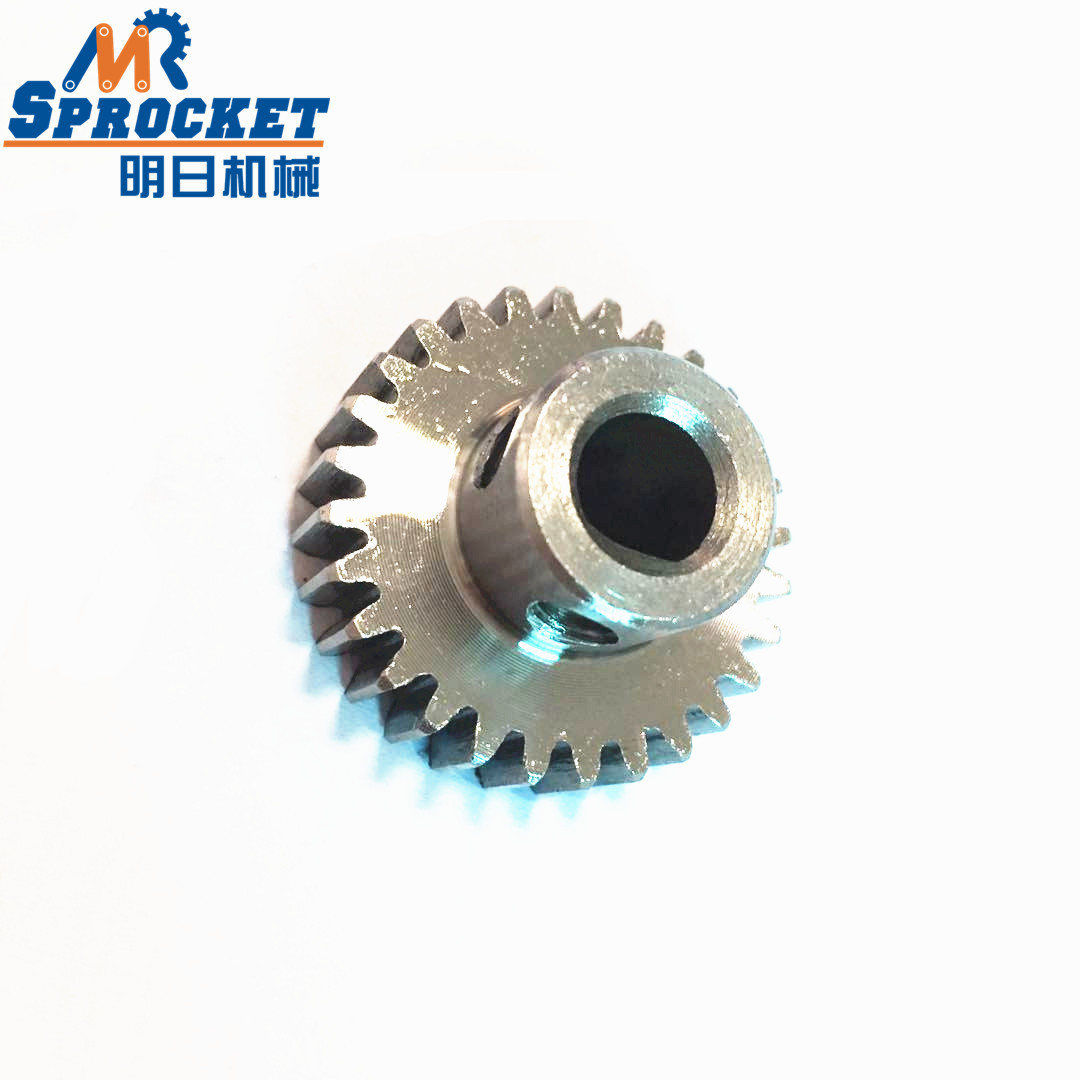

Below is a standard sprocket with a bush and conveyor pin – the most common chain used in industry today. As the sprocket rotates, it drives the bush on the conveyor chain, which in turn drives the chain conveyor.

If product can get between the chain and sprocket – especially if the particles break down and have some moisture – they will get stuck between the bush and sprocket teeth.

This, initially, can increase the wear to both the sprocket and chain. In addition, if it is allowed to build up, it can cause the chain to jump teeth. If you have a twin chain driving your conveyor, this can cause major damage as the two chains are now out of sync and attachments will bend or buckle.

Small improvements with big results

In our experience, the simplest solutions usually work the best and this instance is no different. Working with our factory, we have developed special anti-clog conveyor chain sprockets with a groove at the base of the tooth. Quite simply, it allows any debris build up to fall away leaving the driving flank of the sprocket clean to drive the chain.

By adding this groove to the sprocket, it has drastically increased the life of the sprocket and helped the life of the chain. Should the conveyed material be abrasive or hard, then the need for anti-clog conveyor chain sprockets is even greater.