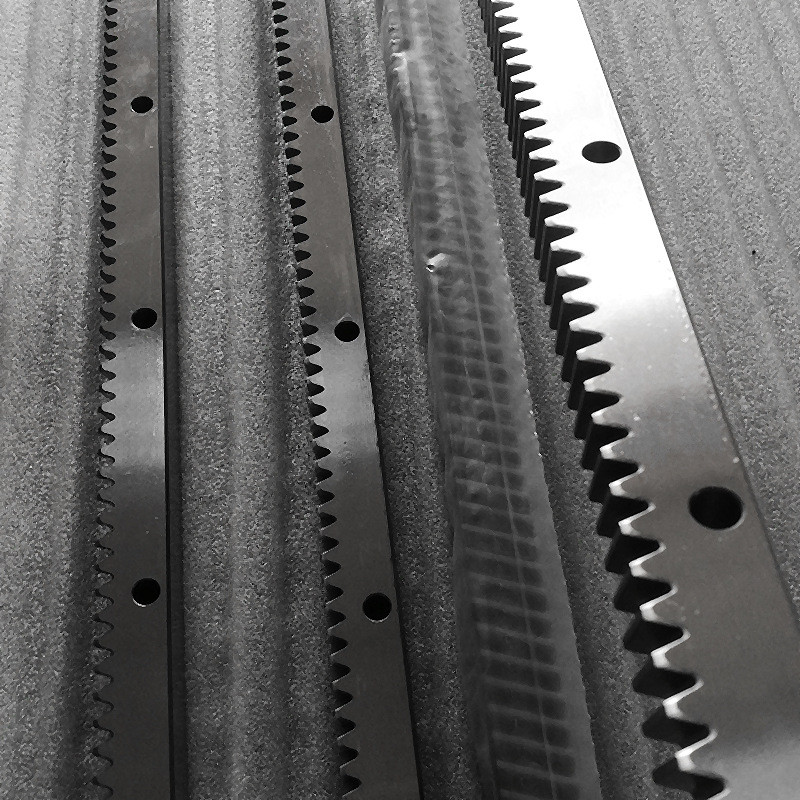

YQ Transmission Product,Rack,Profession

Rack MaKing

The role of the rack and its manufacturing method, the influence of the material of the gear on the performance of the gear, according to the hardness, the tooth surface can be divided into two types: soft tooth surface and hard tooth surface. Soft tooth

The wheel load capacity is low, but it is easier to manufacture and has good running-in performance. It is mostly used for transmission size and weight without strict restrictions, and small

Mass production of general machinery. Because the small wheels bear a heavier burden in the matched gears, the working life of the large and small gears is approximately

Equal, the hardness of the tooth surface of the small wheel is generally higher than that of the large wheel. The hardened gear has a high load-bearing capacity. It is after the gear is cut,

After quenching, surface quenching or carburizing quenching treatment, in order to improve the hardness. But in heat treatment, gears will inevitably produce

Therefore, after the heat treatment, grinding, grinding or fine cutting must be carried out to eliminate errors caused by deformation and improve the gear

The precision. The commonly used steels for manufacturing gears are quenched and tempered steel, quenched steel, carburized and quenched steel and nitrided steel. Cast steel is slightly stronger than forged steel

Low, often used for larger gears; gray cast iron has poor mechanical properties and can be used in light-load open gear transmissions; ductile

Cast iron can partially replace steel to make gears; plastic gears are mostly used in places where light loads and low noise are required.

Generally, steel gears with good thermal conductivity are used.