Industrial Chain and Sprocket Manufacturer

Home / All

Blog

- The Difference Between Spur, Helical, Bevel, and Worm GearsMay 14,2024Spur gears have straight teeth and are used for parallel shafts, offering simplicity and cost-efficiency. Helical gears feature angled teeth, providing smoother and quieter operation for parallel or perpendicular shafts. Bevel gears have conical shapes for intersecting shafts, allowing angular direction changes. Worm gears consist of a screw (worm) meshing with a gear, enabling high reduction ratios and torque transmission at right angles with a compact design.

- Intro of CouplingApr 16,2024Industrial couplings are essential components in machinery, connecting shafts to transmit power efficiently while accommodating misalignment and reducing vibration. They come in various types, including jaw, gear, and disc couplings, each suited for different applications. These couplings ensure reliable power transmission and help protect machinery from damage, ensuring smooth operation in industrial settings.

- Coupling Maintenance And FailureApr 16,2024Industrial coupling maintenance involves regular inspection for wear, misalignment, and lubrication. Common failure modes include fatigue, wear, and misalignment-induced damage. Symptoms of coupling failure include excessive vibration, noise, or overheating. Regular maintenance, including lubrication and alignment checks, can prevent premature failure and extend the coupling lifespan. In case of failure, prompt replacement or repair is necessary to avoid costly downtime and equipment damage.

- How To Install and Remove Taper-Lock BushingApr 16,2024This blog talks about how to install and remove taper lock bushing.

- QD Bushing Installation and RemovalApr 16,2024The QD (Quick Disconnect) bushing offers swift installation and removal for efficient power transmission setups. To install, loosen and remove mounting bolts, then insert bolts into jack screw holes as directed. Loosen the bushing gradually until disengaged. For removal, follow the reverse process: insert bolts into removal holes, loosen the bushing until disengaged, then remove bolts and bushing. Ensure proper alignment and torque values throughout the process for optimal performance.

- Engineering Chain for Tackling Big JobsApr 16,2024Engineered for heavy-duty tasks, our Engineering Chain is designed to tackle big jobs with ease. Crafted from high-quality materials and precision-engineered to withstand demanding conditions, this chain ensures reliable performance and durability. Whether for industrial machinery, construction equipment, or other robust applications, our Engineering Chain delivers the strength and reliability you need.

- Intro of Leaf ChainApr 16,2024Industrial Leaf Chain is a robust and reliable solution for heavy-duty lifting applications, offering exceptional strength and durability. Composed of interlocking leaf-shaped links, this chain is designed to withstand high loads and provide smooth and efficient operation in material handling equipment such as forklifts, cranes, and hoists.

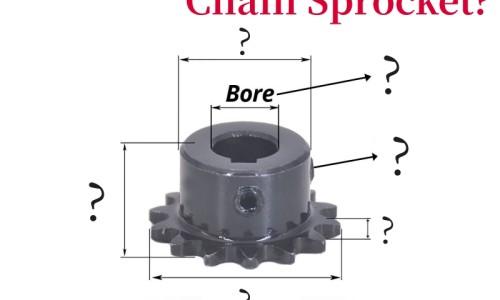

- How to measure Chain Sprockets?Apr 16,2024Measuring industrial chain sprockets involves determining chain type, pitch, and number of strands. Key considerations include sprocket hub style, teeth count, hub diameter, and length through the bore.

- Type Of Industrial Chain SprocketsApr 16,2024Industrial chain sprockets encompass various types, including Type A, B, C, and D categorized by hubs, and plain bore, finished bore, and taper bore based on hole types. They also vary by the number of rows, materials like carbon steel and stainless steel, and specialized designs like idler, QD bushing, split, double pitch, and DS sprockets. Customization for specific applications is available, ensuring versatility and adaptability in industrial settings.

- How To Measure Roller Chains?Apr 16,2024Learn the essential steps and tips for accurately measuring roller chains to ensure optimal performance.

- How to break a roller chain?Apr 16,2024To break a roller chain, locate the chain breaker tool's pin over the chain's pin you wish to remove. Apply pressure to the chain breaker tool until the pin is fully extracted from the chain link. This separates the chain link and allows you to remove or repair the chain as needed.

- How to connect roller chain?Apr 16,2024To connect roller chain, align the ends and insert a connecting link pin. Ensure the pin's head faces toward the direction of chain travel. Press the pin into the chain, leaving a small gap between the link plate and roller. Insert the retaining clip, ensuring it's fully seated in the grooves of the link plates for secure attachment.

Ask CTS?

Having trouble finding the product you need? Send us an email with your question or message, and we'll quickly respond with tailored solutions. We're eager to hear from you! Expect top-notch precision, reliability, efficiency, and performance. Let's redefine excellence together.

- China's professional power transmission manufacturer

- We offer customized product services and free samples to meet our customers' needs.

- Some of our products are mass-produced and kept in stock, ready for immediate shipment.

- Contact CTS

- Name