What You Need to Know About ANSI Roller Chains

ANSI roller chains adhere to the specifications set by the American National Standards Institute (ANSI). ANSI roller chains are often used in systems where durability, precision, and cost-effectiveness are essential. They consist of several key components, including chain rollers, links, pins, and side plates, that transfer energy and motion between mechanical parts.

Before the establishment of ANSI standards, roller chains were often made to varying specifications, leading to compatibility issues when replacing chains from different manufacturers. The ANSI standardization of roller chains provided a universal sizing system that made them compatible across a wide range of machinery and systems.

ANSI Standard Roller Chains Size

Key Components of ANSI Roller Chains

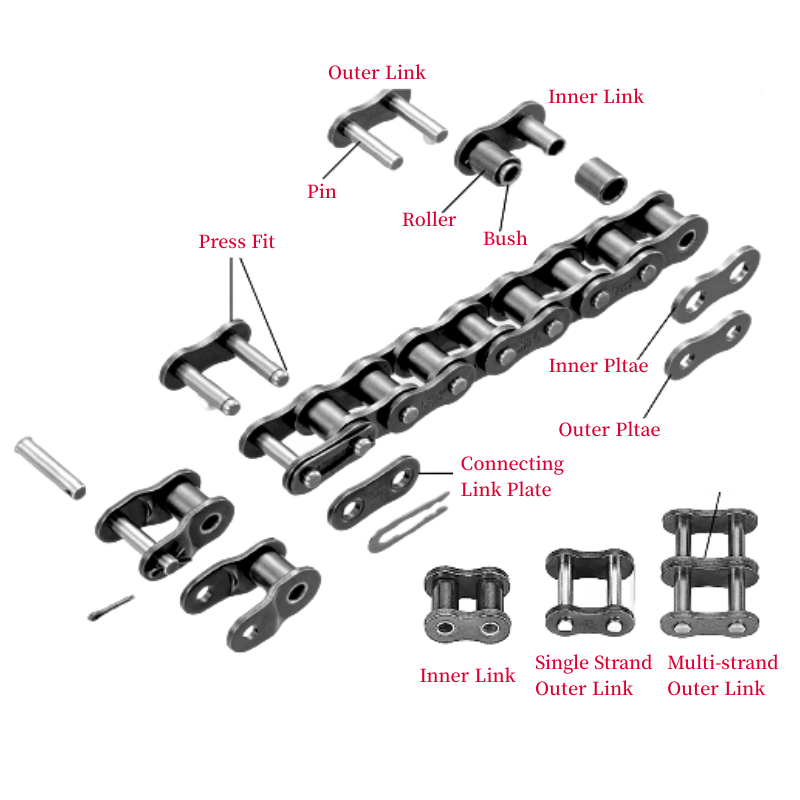

Rollers: These cylindrical components are responsible for engaging with sprockets. The rollers help reduce friction, allowing for smoother operation.

Pins: The pins are the central connectors that hold the chain's links together, ensuring the entire chain moves as a unit.

Bushings: Located between the pins and rollers, bushings act as a bearing surface, helping to reduce wear and increase the chain’s lifespan.

Side Plates: These plates provide structural integrity to the chain, holding the rollers, pins, and bushings together. They are typically made of durable steel to withstand the stresses of operation.

Links: The individual pieces that make up the entire chain. The number of links and the design of the chain depends on its size and application.

Types of ANSI Roller Chains

How to Choose the Right ANSI Chain for Your Application

Pitch Size: This refers to the distance between two adjacent pins and is one of the most important specifications to match with your machinery. Common sizes are ANSI 40, ANSI 50, ANSI 60, and so on.

Load Capacity: Ensure the chain can handle the operational load of your system. For higher loads, you might need a double or triple-strand chain.

Material: If your chain will be exposed to corrosive environments, opt for stainless steel or chains with protective coatings. For high-temperature applications, certain chains are designed to resist heat.

CTS | Professional Roller Chain Supplier

CTS®-ChinaTransmissionS is a professional roller chain supplier with over 14 years in the power transmission industry.

As a professional roller chain supplier, our experienced technical team always learns the latest manufacturing technology.

We offer various industrial chain options: roller chains, conveyor chains, stainless steel chains, heavy-duty roller chains, double-pitch roller chains, roller chain attachments, etc.

If you want to replace your roller chains or have any questions about roller chains, please contact us.