What Is Idler Sprockets?

Idler Sprockets

An idler sprocket is a free-spinning gear that doesn’t transmit power like a drive sprocket. Instead, its primary role is to guide and support the chain. It ensures proper tension, alignment, and smooth operation in a mechanical system.

The Function of an Idler Sprocket

Reducing Chain Slack

Chains naturally loosen over time, and idler sprockets take up that slack, maintaining optimal tension.

Improving Chain Alignment

Misaligned chains can damage machinery. An idler sprocket ensures the chain stays on track, preventing costly breakdowns.

Enhancing System Efficiency

A well-placed idler sprocket minimizes wear and tear, boosting overall system efficiency and extending the lifespan of components.

ANSI Idler Sprockets with Ball Bearing

Metric Idler Sprockets

Types of Idler Sprockets

Fixed Idler Sprockets

Fixed idler sprockets are stationary and ideal for systems with consistent operating conditions.

Adjustable Idler Sprockets

Adjustable idler sprockets allow flexibility, making them perfect for systems where chain tension fluctuates.

Bearing-Based Idler Sprockets

Idler sprockets with ball bearings are common in high-speed systems and are designed for smoother rotation and reduced friction.

How To Choose The Right Idler Sprockets

Consider Chain Compatibility

Ensure the idler sprocket matches the chain type and size for seamless operation.

Evaluate Load and Stress Factors

Choose an idler sprocket that can handle the load without excessive wear.

Inspect for Durability Requirements

For harsh environments, opt for materials that resist corrosion and wear.

Other Chain Sprockets

| Type | Taper Bore Sprocket | Advantages | Disadvantages |

| Basic sprocket with an undersized bore for customization. | Customizable to fit any shaft size; flexible for various applications. | Requires additional machining; more labor-intensive. | |

| Pre-machined sprocket with a finished bore, keyway, and set screws. | Ready-to-use; quick installation; no extra machining needed. | Limited flexibility for different shaft sizes. | |

| Sprocket with a tapered bore that uses a taper bushing for installation. | Easy to install/remove; can be adapted to multiple shaft sizes with different bushings. | Slightly more complex installation; requires taper bushing. |

CTS® | Professional Industrial Sprocket Manufacturer

Partnering with a reliable industrial sprocket manufacturer ensures smoother operations, reduced downtime, and long-term cost efficiency.

CTS® is a professional industrial sprocket manufacturer with over 14 years of experience in the power transmission industry. We have our industrial sprocket factory and a professional technical team that can provide technical support and a responsive after-sales team after-sales team.

As a professional industrial sprocket manufacturer with mature industrial sprocket manufacturing technical, we can not only produce standard industrial sprockets(ANSI/DIN/KANA) but also customize industrial sprockets according to your specific needs.

If you have any questions about industrial sprockets and other transmission parts, please contact us to help you.

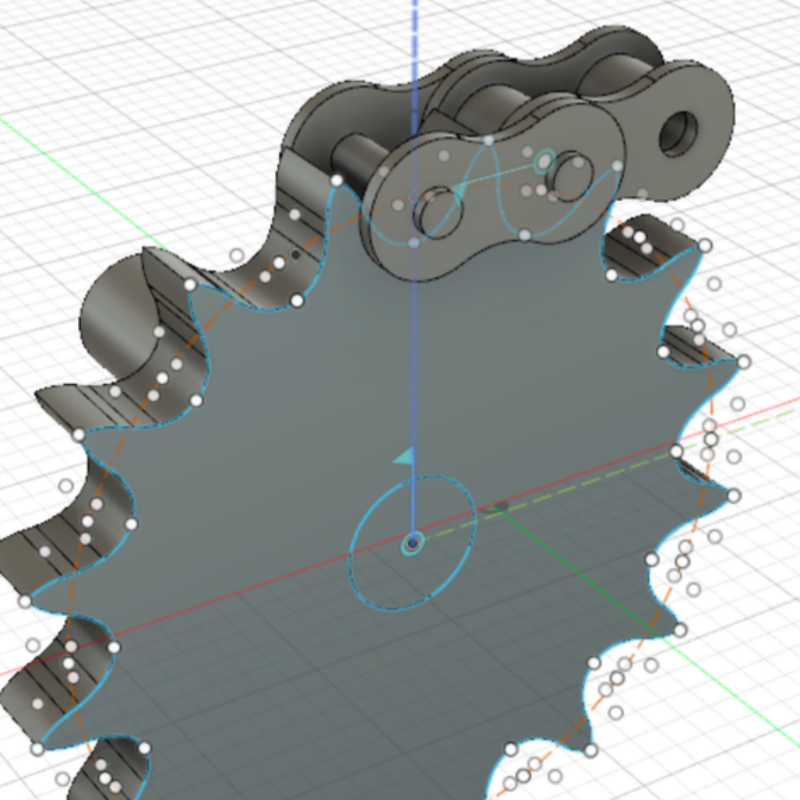

Industrial Sprocket CAD

CNC Machining

Customized Sprockets

Customers Good Review