The Custom Process for Industrial Sprockets

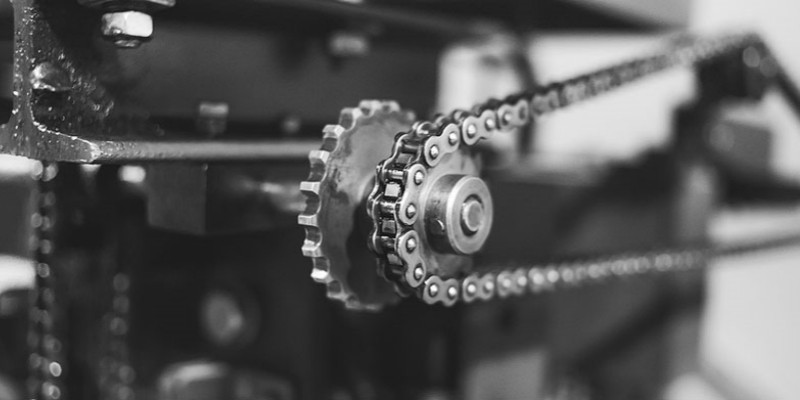

Industrial sprockets play a vital role in various applications, from conveyors to heavy-duty machinery. However, many industries require custom-designed sprockets to meet unique performance needs. Customizing industrial sprockets involves several stages of engineering, precision, and testing. Below, we’ll explore the complete process of industrial sprocket customization, from the initial design phase to final production.

Understanding the Requirements

The first and most important step in creating a custom industrial sprocket is understanding the specific application requirements. Our engineers work closely with clients to gather detailed data on the operating environment and performance expectations. Key parameters typically include:

• Torque and speed requirements of the machine.

• Load capacity and the stresses the sprocket will face.

• Operating conditions, such as temperature, humidity, or exposure to chemicals.

• Specific industry needs, for example, high precision in aerospace or heavy-duty durability in mining.

Design and Conceptualization

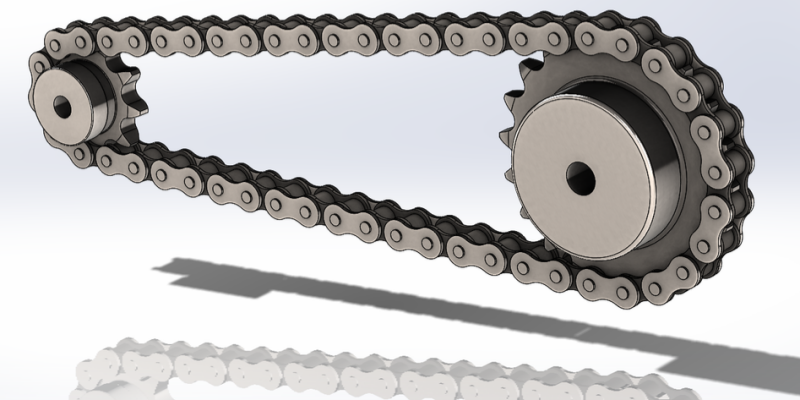

Once the application needs are clear, the design phase begins. Our engineers use advanced CAD (Computer-Aided Design) software to create 3D models of the sprocket. This allows for detailed visualization and adjustments before any physical manufacturing occurs.

Several factors are considered during the design process:

• Tooth profile: The shape and size of the industrial chain sprocket’s teeth are critical for proper engagement with the chain, ensuring smooth operation and minimal wear.

• Pitch diameter: The distance between the centers of the industrial sprocket’s teeth, which must match the chain pitch precisely.

• Bore size and keyway: These features ensure that the industrial sprocket can fit securely onto the shaft it will drive.

• Material selection: Depending on the operating environment, different materials may be used. Steel, stainless steel, aluminum, and various alloys are common, each offering unique strengths, corrosion resistance, or weight characteristics

Precision Machining

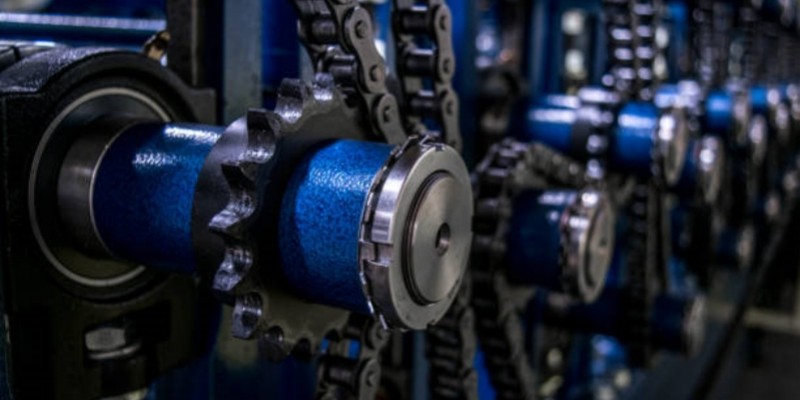

After the design is finalized, the next step is precision manufacturing. Modern custom industrial sprocket production involves advanced CNC (Computer Numerical Control) machines, which ensure high levels of accuracy and consistency.

Key machining processes include:

• Milling and turning: These techniques are used to shape the industrial sprocket from raw materials, ensuring the precise geometry of the teeth, bore, and keyways.

• Hobbing: This process is specifically used to create the industrial sprocket’s teeth with the correct profile and spacing

• Boring: This process ensures the inner bore of the industrial sprocket matches the shaft it will be mounted on, providing a perfect fit.

Industrial Sprocket Heat Treatment

Once machining is complete, many custom industrial sprockets undergo heat treatment to improve their strength, hardness, and wear resistance. Common processes include:

• Quenching and tempering: These techniques alter the metal’s internal structure, increasing its toughness and durability.

• Induction or flame hardening: This is often used for the teeth of the industrial sprocket, giving them a hard outer layer to resist wear while maintaining a tough core

Industrial Sprocket Surface Finishing

After heat treatment, surface finishing processes are applied, such as:

• Polishing to improve aesthetics and reduce friction.

• Plating or coating for corrosion resistance in harsh environments

Quality Assurance

Throughout the production process, strict quality control measures are in place to ensure that each industrial sprocket meets the required specifications. These include:

• Dimensional inspections to verify that the industrial sprocket matches the 3D design down to the millimeter.

• Material testing to ensure the strength and durability of the industrial sprocket.

• Functional checks to confirm that the industrial sprocket will perform as expected when installed

Testing and Validation

Before shipping, custom industrial sprockets are subjected to rigorous testing to ensure they meet performance standards. These tests may include:

• Simulated load testing to verify the sprocket can handle the stresses it will face in operation.

• Wear and endurance testing to determine the sprocket’s lifespan under harsh conditions

Deployment and Integration

Once the industrial sprockets pass all testing, they are ready for shipment. Our engineers may assist with the installation to ensure that the industrial sprockets are properly aligned and fitted. This is critical to prevent premature wear or failure, as improper alignment can lead to excessive strain on the industrial sprocket and chain.

CTS - Professional Industrial Sprocket Manufacturer

CTS®-ChinaTransmissionS is an industry-leading industrial sprocket manufacturer. We have been providing industrial sprocket solutions for 14 years. We offer standard industrial sprockets and also can customize industrial sprockets to according your requirements.

CTS-ChinaTransmissionS is a professional industrial sprocket manufacturer, any questions let us know, Contact us, and our technicians will be happy to help you!