Roller Chain Coupling

About Roller Chain Coupling

Making sure rotating shafts are aligned correctly is a big challenge in factories. Even if they start out in the right position, the way the machinery operates can cause them to become misaligned. This can damage the drive shafts and other parts of the machines, leading to expensive downtime and repairs.

Roller chain couplings offer a straightforward yet highly effective solution to this issue. Comprising a coupling chain and a pair of coupling sprockets, they introduce a crucial clearance around the driven components. This inherent flexibility allows for minor misalignments between shafts without adversely affecting the overall system performance.

Moreover, roller chain couplings act as a protective barrier, preventing bearings from overheating and abrasion. This feature not only ensures the smooth operation of machinery but also prolongs its lifespan, minimizing maintenance costs and maximizing productivity.

Installation of Roller Chain Coupling

Roller chain coupling features a unique single-pin design that simplifies the installation process. Just follow these easy steps:

Step 1: Install the oil seal on each hub.

Step 2: Align the shafts and coupling components.

Step 3: Adjust the distance between the sprocket faces.

Step 4: Thoroughly lubricate the coupling chain.

Step 5: Install the chain onto the couplings using the single-pin connecting link.

Step 6: Firmly close and fasten the coupling cover (optional, depending on operating conditions).

In general, installing roller chain couplings is much simpler and faster compared to traditional rigid shaft couplings.

Application of roller chain coupling

Roller chain couplings are great for heavy-duty tasks, like those in tire manufacturing. They're also popular in farming and mining, especially for machines like bucket elevators and incline conveyors.

When you set up the coupling, the torque spreads evenly across the roller chain and all the sprocket teeth. This even distribution helps your chains and other parts last longer, saving you money on repairs.

In addition, you can add covers to shield against dust, water, and other stuff that might harm the chain. These covers can even hold lubricant to keep everything moving smoothly, making your equipment last even longer.

Advantage of roller chain coupling

Easy to install

High efficiency

Perform effectively in abrasive and wet environments

Couplers remain secure even when shafts are misaligned

You can connect multiple shafts with a single chain

They are relatively safe, with no risk of fire hazards

Coupling chains can operate over both long and short distances

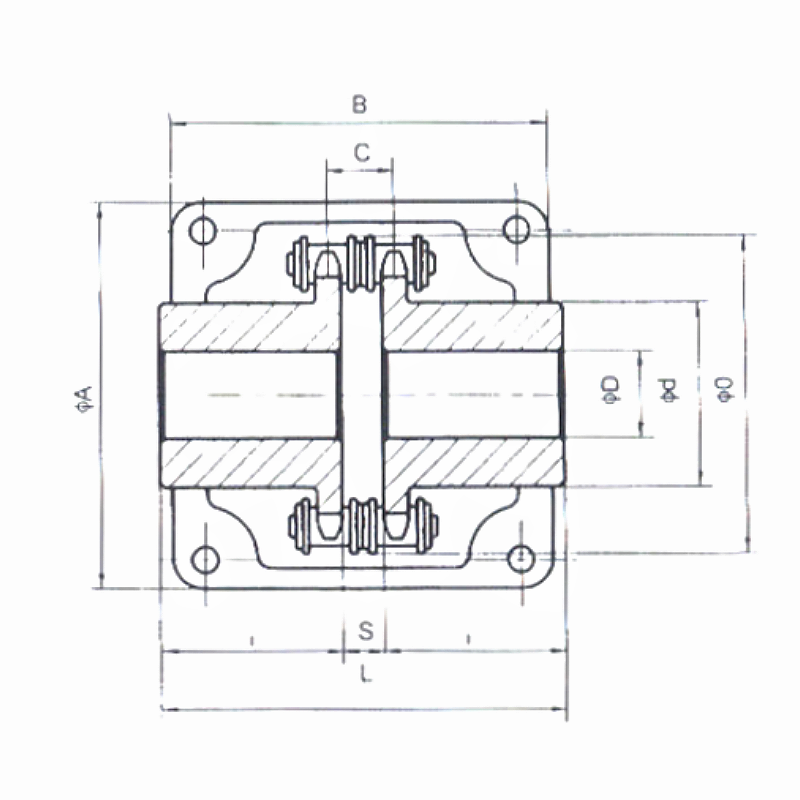

Roller Chain Coupling Size

Here is the parameter information about the Roller Chain Coupling for your reference.

To browse our excellent products, please visit our ChinaTransmissions.com or contact us via email at info@chinatransmissions.com or call 0086-18667944319(WhatsApp/WeChat).

If you have any questions, please feel free to contact us, CTS® professional technicians will be happy to help you!