How To Measure V Belt Pulley?

One of the growing and most widely used product types in the power transmission and automotive industries is the V-belt pulley, also known as a "pulley.". A V-belt pulley is an accessory that transfers energy between shafts with the aid of a V-belt.

However, to keep this important pair of equipment running properly, it is necessary to ensure that the proper V-pulley is replaced when the old equipment wears out. To do this, you need to know your V-pulley's size, dimension, and type so that the replacement will function properly. Learning how to measure a V-belt pulley and calculate its dimensions is a simple task.

V-belt Pulley Measuring Tools

Digital Caliper: For precise measurements of diameters and grooves.

Measuring Tape: Ideal for larger pulleys.

Straightedge: Helps check alignment.

Feeler Gauge: Measures groove angle and depth.

Key Dimensions of a V-Belt Pulley

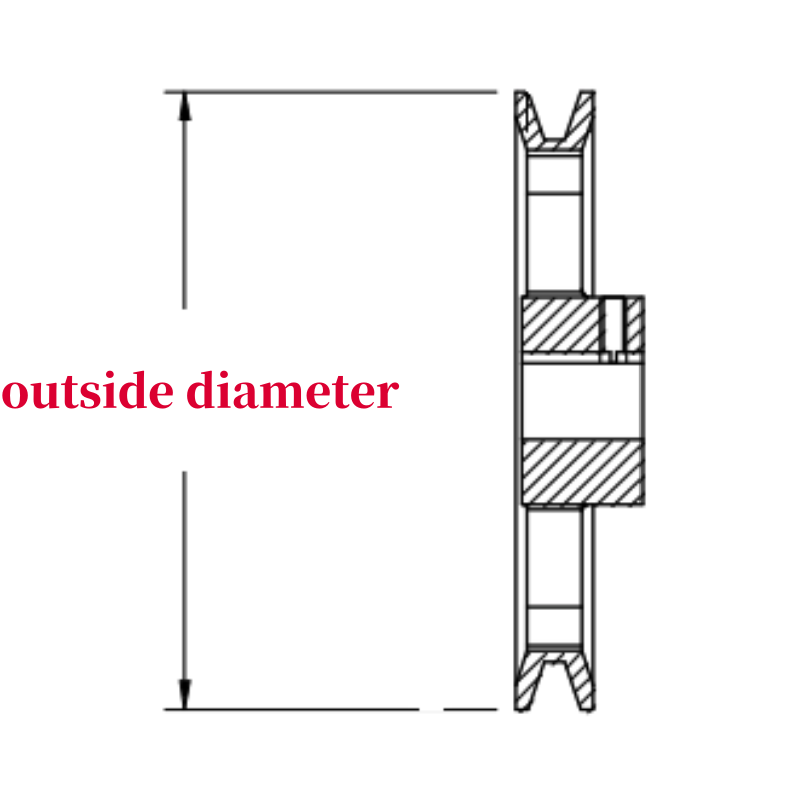

| Pulley Diameter | Measure the outside diameter by placing the caliper or tape across the widest part of the pulley.

|

| Bore Diameter | Check the internal diameter of the pulley where it fits the shaft. This ensures a snug fit.

|

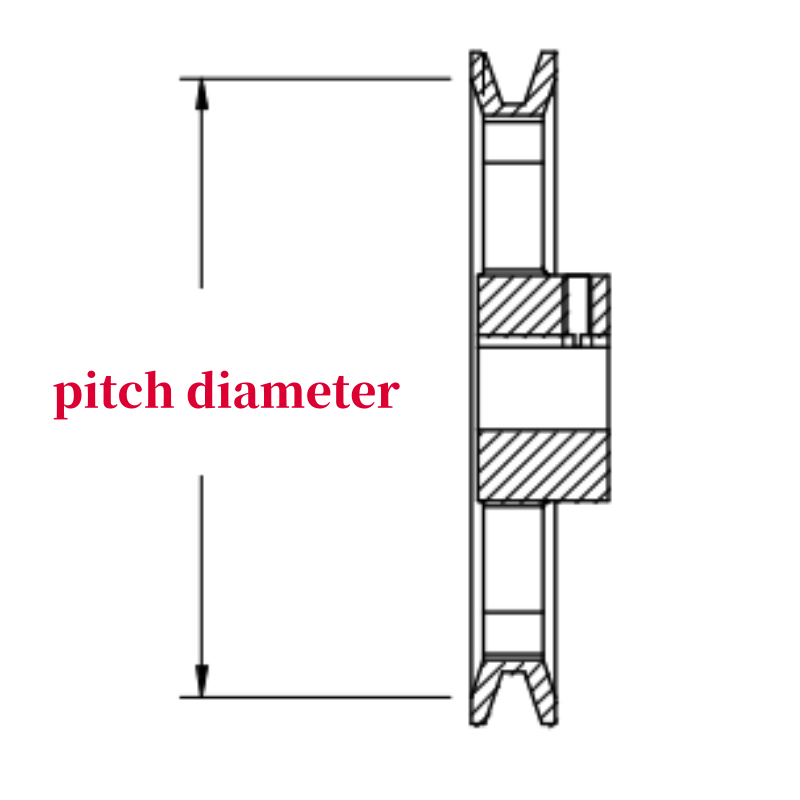

| Pitch Diameter | This is the effective diameter where the belt makes contact. You can calculate it using the outside diameter and groove angle.

|

| Pulley Width | Use a straightedge or caliper to measure the width across the pulley face. |

Step-by-Step Guide to Measuring V-Belt Pulleys

Step 1

Measure the outside diameter of the pulley.

Step 2

Then measure the pitch diameter. This measurement represents the diameter of the belt itself as it runs in the pulley. If you already know the size of the V-belt, or if the pulley and belt are badly worn, you do not need to perform this step.

Pitch Diameter=Outside Diameter−2×(Belt Thickness)

Step 3

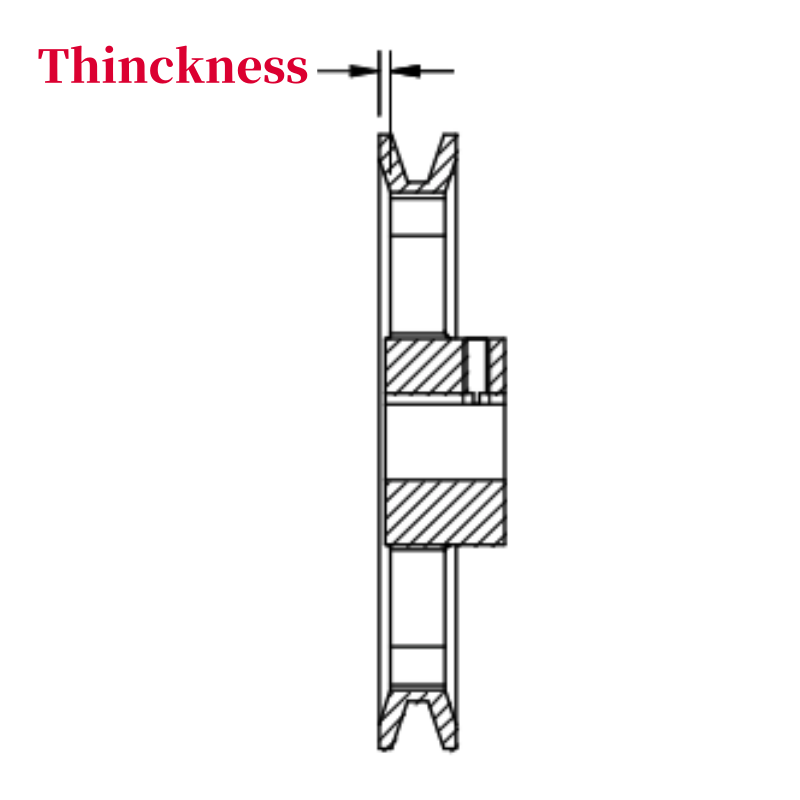

Measure the wall thickness of the pulley.

Step 4

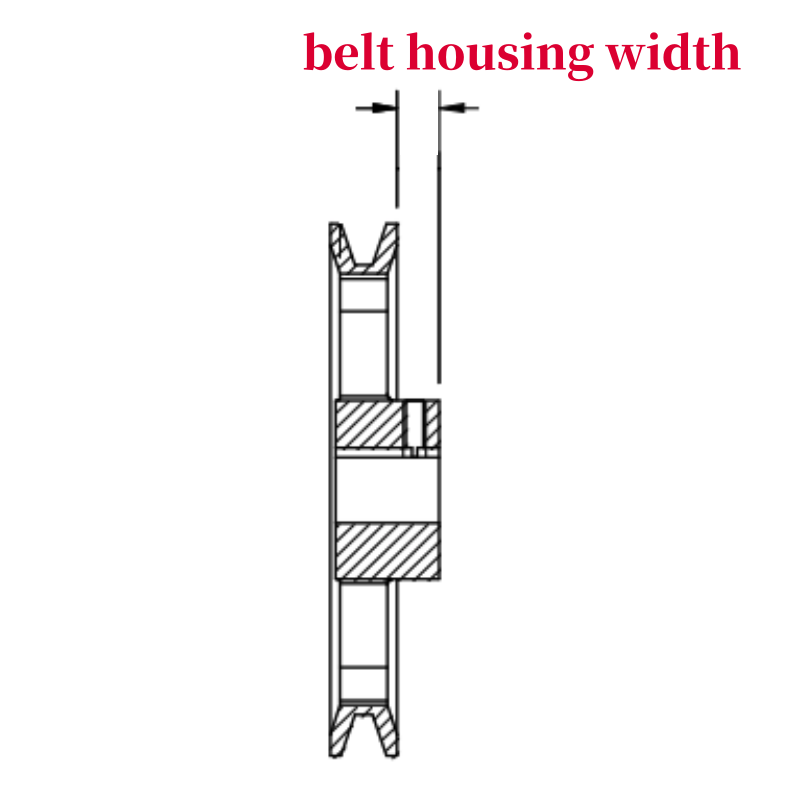

Measure the total width of the belt housing, where the belt runs in the pulley.

Step 5

If the pulley has a hub that extends beyond the width of the "belt housing," it is often best practice to measure the extension of the hub.

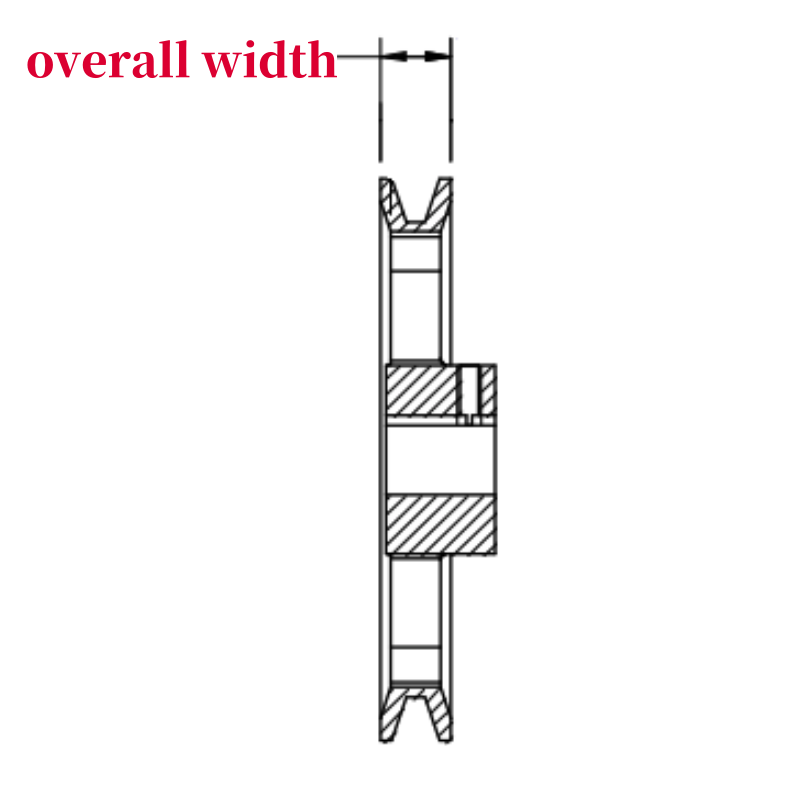

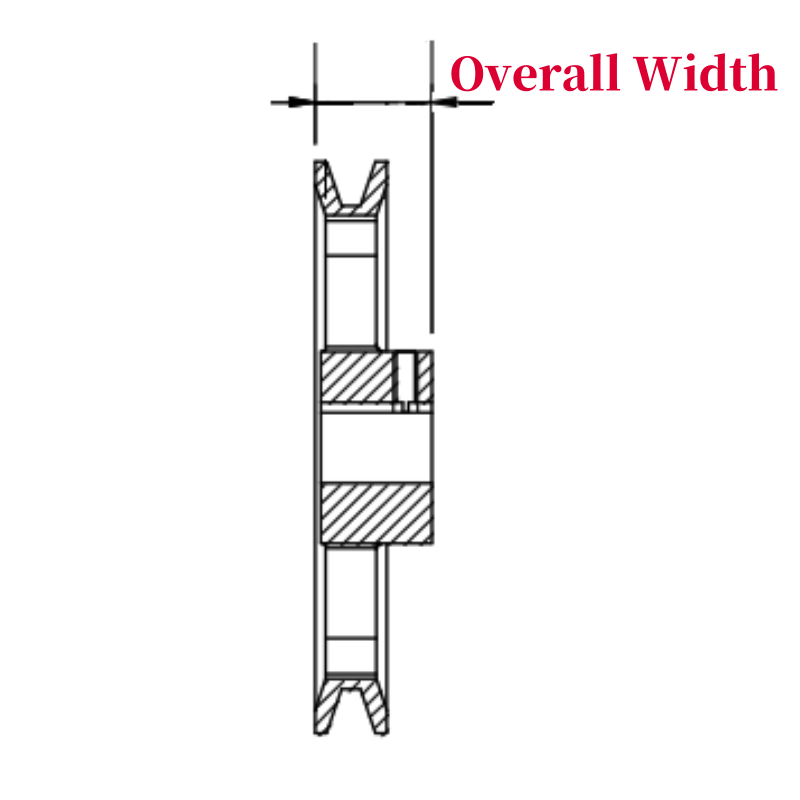

Step 6

The final measurement is the entire overall width of the pulley. In most cases, this will specify the type or series of belts used.

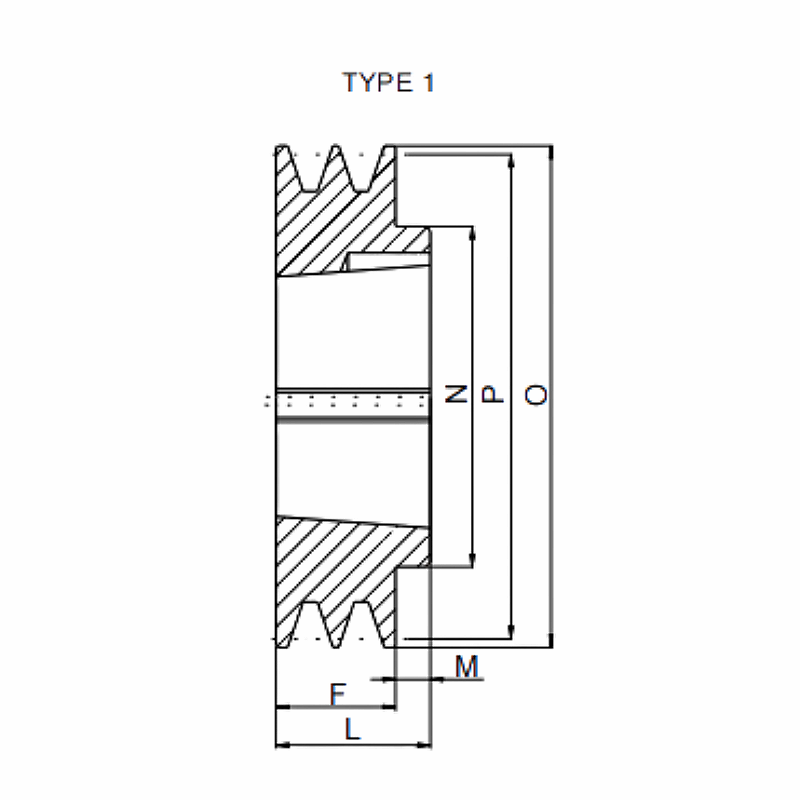

Metric V-Belt Pulley Type

Common Measurement Errors and How to Avoid Them

Misalignment of Tools

Always keep your tools perpendicular to the surface for accuracy.

Overlooking Groove Depth

Ensure the grooves are clean to avoid miscalculations.

Misinterpreting Pitch Diameter

Double-check calculations to ensure compatibility with belts.

Maintenance Tips for V-Belt Pulleys

✔ Clean grooves regularly to prevent debris buildup.

✔ Inspect for wear and tear, especially on edges.

✔ Lubricate bearings to extend the pulley's lifespan.

Choose CTS® V-belt Pulley

CTS®-ChinaTransmissionS is a professional v-belt pulley manufacturer in the power transmission industry. We can provide solid bore and taper bore SPA, SPB, SPC, and SPZ V-belt pulleys. In addition, we manufacture timing belt pulleys and can provide customized service for you.

If you have any questions about industrial transmission chains, please contact us.